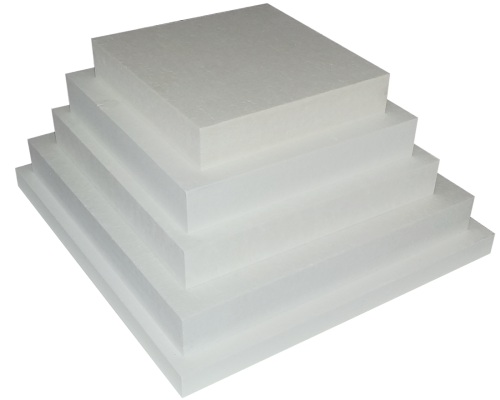

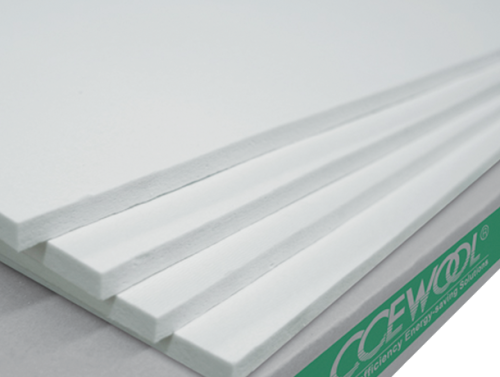

CCEWOOL® Ceramic Fiber Board 2600 is a zirconia-containing high-temperature insulation board with 15-17% zirconia in its raw materials. It offers exceptional chemical stability and strength compared to standard ceramic fiber boards.

Get a Quote-

Enhanced High-Temperature Resistance with Added Zirconia

With the addition of ≥15% zirconia, the product effectively resists excessive shrinkage at high temperatures, offering excellent heat resistance and resilience against chemical and mechanical stresses.

-

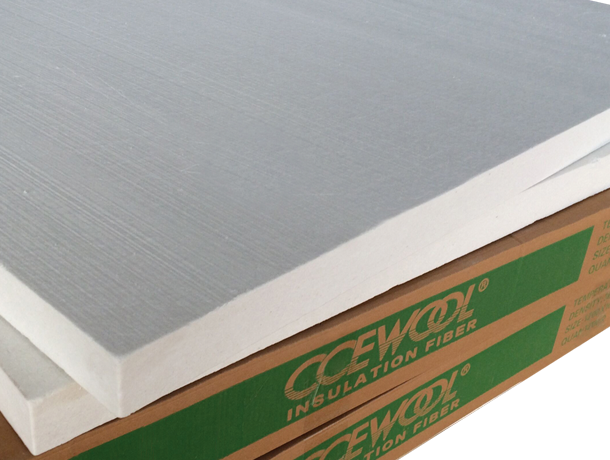

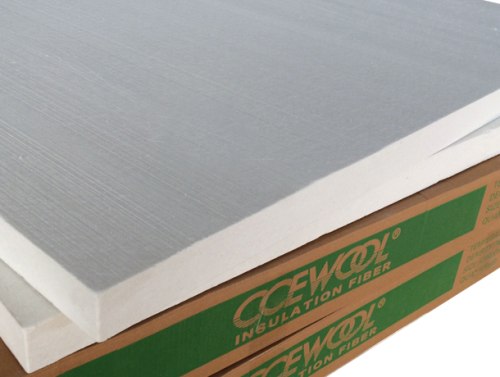

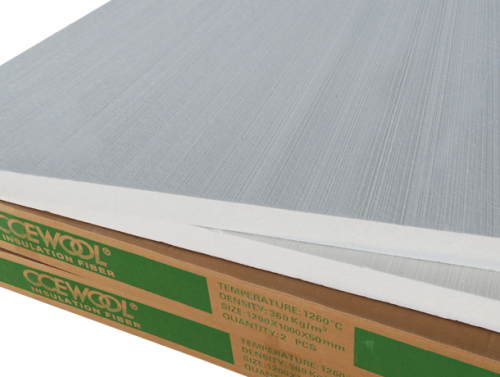

Fully Automated Production for Enhanced Precision and Stability

With fully automated CNC production equipment, our ceramic fiber boards boast greater stability, flatness, and dimensional accuracy than those made through traditional vacuum forming, ensuring superior product performance.

-

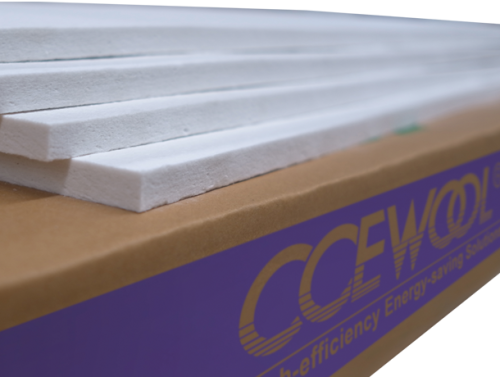

Efficient Drying for Consistent Quality

Our fully automated drying system completes thorough and uniform drying within 2 hours, ensuring compressive and flexural strengths above 0.3 MPa, further enhancing product quality and durability.

-

Precision Cutting with Zero Tolerance

Using fully automated CNC machinery, we can cut boards to meet specific dimensions and shapes, achieving nearly zero dimensional error to satisfy high-precision application requirements.