CCEWOOL® Polycrystalline Wool Fiber Board 2912 offers superior thermal stability and high insulation capacity compared to ceramic fiber boards, especially at extremely high working temperatures, helping to reduce energy costs and cycle time.

Get a Quote-

Polycrystalline Fiber Formed by Wet Process with 73% Alumina Content

Manufactured with polycrystalline fiber cotton and binders through a wet-forming process, this product has an alumina content of up to 73%, ensuring exceptional performance in high-temperature environments.

-

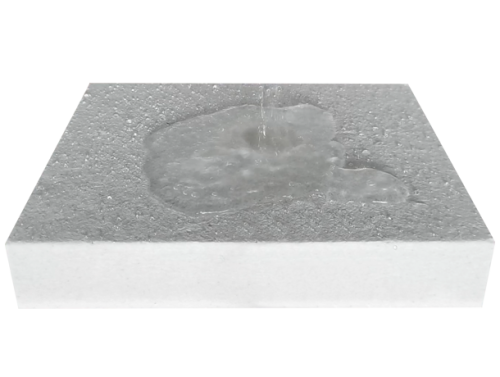

Outstanding Insulation and High-Temperature Stability

Ideal for applications requiring high stability and temperature resistance, this material offers excellent insulation properties, along with superior thermal shock resistance, wear resistance, and chemical erosion protection.

-

High Rigidity and Fracture Resistance for Specialized Applications

With enhanced rigidity and fracture resistance, this product is particularly suited for applications where anti-sagging is essential, ensuring reliability and stability over long-term use.

-

Custom Specifications to Meet Precise Application Needs

We provide standard sizes and shapes commonly available on the market and offer customized solutions tailored to specific application requirements, meeting precise needs across different working conditions.