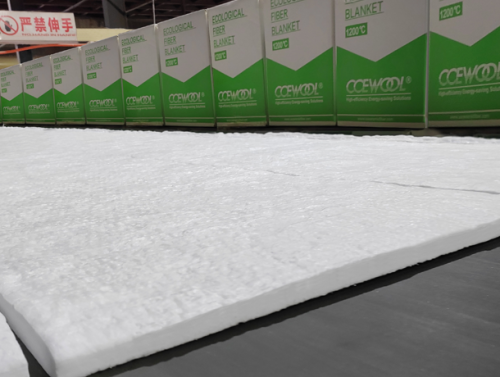

Compared to traditional soluble fiber blankets, the CCEWOOL® Low Biopersistent Fiber Blanket LT Pro contains more than 30% fiber, resulting in lower thermal conductivity and better tensile strength. Certified by the German Fraunhofer Laboratory for solubility testing.

Get a Quote-

Biodegradable Fibers, Safe and Eco-Friendly

Our fibers are made from alkaline earth silicate (AES) components such as SiO₂, MgO, and CaO, featuring biodegradable properties to ensure safety for human health and environmental friendliness.

-

Ultra-Low Slag Ball Content, Reduced Dust Interference

The ultra-low slag ball content in the fibers enhances operability, effectively reducing dust interference and providing a cleaner working environment.

-

Excellent Thermal Stability, Maintained Fiber Structure

With outstanding thermal stability, the fibers retain their original soft structure even at the highest continuous operating temperatures. Free from binders or lubricants, they do not emit any smoke or odors during the first firing.

-

Globally Certified, Safe with No Carcinogenic Risk

Certified by the Fraunhofer Institute in Germany and compliant with the Globally Harmonized System (GHS) standards, the product requires no carcinogenic warning labels, ensuring safe and worry-free use.