CCEWOOL® Inorganic Ceramic Fiber Board does not blacken at high temperatures, is smokeless and odorless, and features excellent strength and hardness. Its strength does not significantly decrease after a fire.

Get a Quote-

Pure Inorganic Ceramic Fiber Board to Meet Market Demands

In response to market needs, we have developed pure inorganic ceramic fiber boards and inorganic custom shapes that are suitable for various high-temperature and smoke-free applications.

-

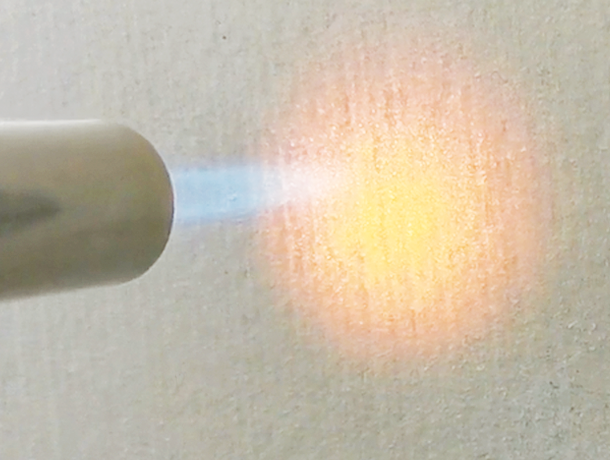

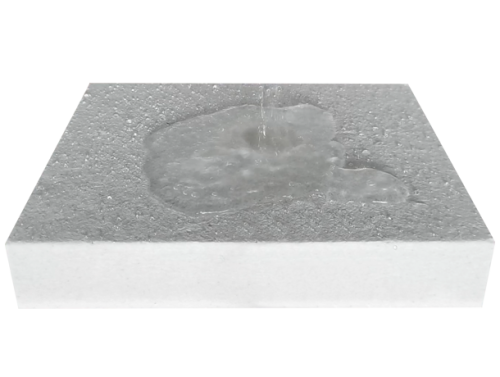

Inorganic Binder Technology for High-Temperature Stability

Using an exclusive production line with inorganic binders, this product remains smoke-free, odorless, and color-stable at high temperatures, making it environmentally friendly and ideal for long-term use.

-

Exceptional Strength, Retaining Integrity After Fire

With outstanding strength and hardness, the product maintains its integrity even after exposure to fire, ensuring lasting safety and stability.

-

Widely Used in Household Appliances and Smoke-Free Equipment

This product is extensively used in household appliances and smoke-free heating equipment, such as electric stoves, wall-mounted heaters, and spinning ducts, offering efficient insulation and reliable safety protection.