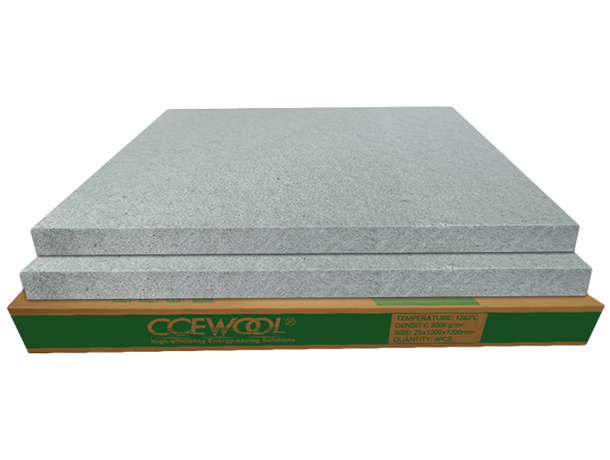

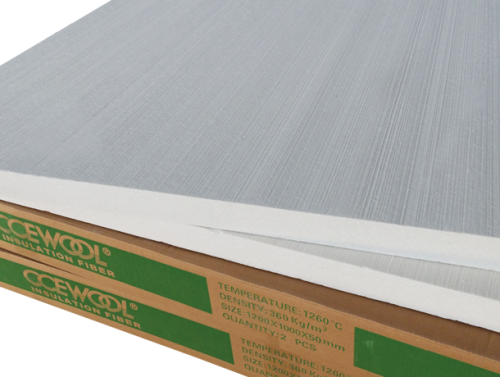

CCEWOOL® 1900 LTC Fiber Board is a vacuum ceramic fiber board with a thermal conductivity ≤0.1W/(m.k), offering better insulation effects and an insulation efficiency 1.2-1.5 times that of traditional lightweight refractory materials.

Get a Quote-

Innovative In-House Development

Our independently developed products utilize a combination of nanotechnology and infrared-blocking technology to enhance overall performance, achieving superior insulation effects.

-

Lower Thermal Conductivity

With a thermal conductivity significantly lower than traditional lightweight refractory materials, insulation efficiency is improved by 1.2 to 1.5 times, delivering prolonged thermal performance.

-

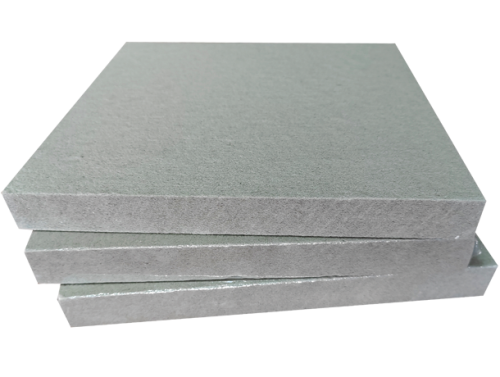

Efficient Composite Structure to Reduce Heat Transfer

The composite design, integrating ceramic fibers with high-efficiency insulating additives, minimizes heat transfer through convection, conduction, and radiation, effectively lowering thermal conductivity across the board.

-

Ultra-Low Thermal Conductivity, Leading-Edge Insulation Material

With its ultra-low thermal conductivity, this product outperforms most insulation materials on the market, offering a superior alternative to conventional ceramic fiber boards.