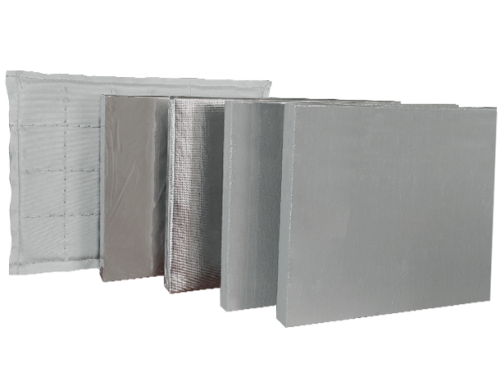

- Kiln Insulation:

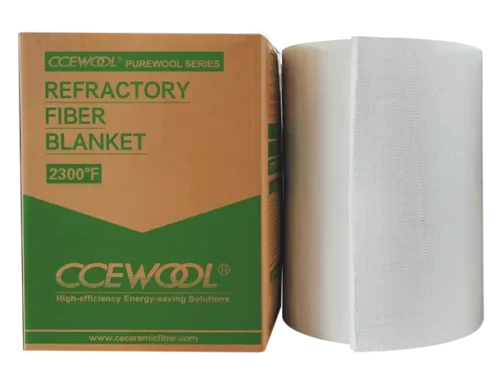

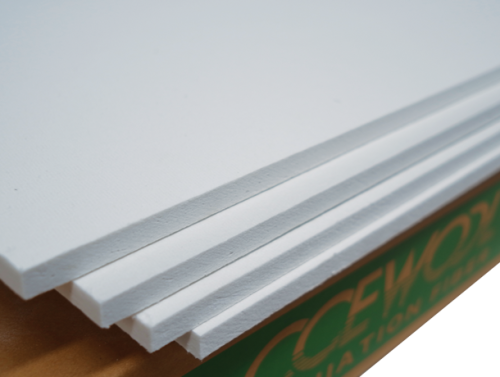

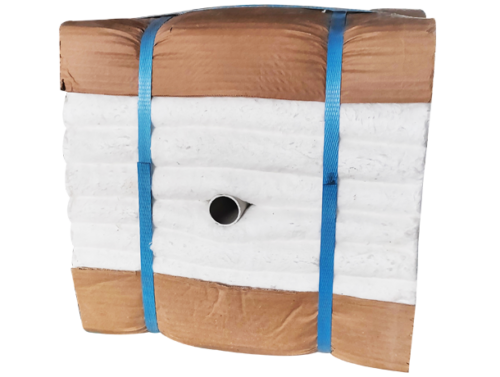

Kilns, as high-temperature equipment, must be equipped with efficient insulation systems. Common insulation materials include ceramic fiber blankets, ceramic fiber modules, refractory bricks, and insulation boards. These materials can withstand high temperatures, prevent heat loss, and improve kiln thermal efficiency. - Pipeline Insulation:

In aluminum smelting and processing, high-temperature liquid aluminum needs to be transported through pipelines. Insulating these pipelines can prevent heat loss and ensure temperature stability during transportation. Common insulation materials include rock wool blankets, glass fibers, and composite insulation layers. - Electrolytic Cell Insulation:

The insulation performance of electrolytic cells directly affects electrolysis efficiency. High-temperature refractory materials and composite insulation structures are typically used to ensure electrolyte temperature stability and reduce heat loss. - Aluminum Processing Equipment Insulation:

Aluminum processing equipment such as melting furnaces, hot rolling mills, and extrusion machines also require insulation treatment to enhance thermal efficiency and processing efficiency. Insulation materials include high-temperature fiber blankets, refractory bricks, and insulation coatings.

Application Solutions

-

Rotary Kiln and Suspension RoasterLearn More

Rotary kilns are mainly used in the roasting of bauxite. In a high-temperature environment, bauxite is roasted in the rotary kiln to convert it into alumina. Suspension roasters are used for processing bauxite or alumina.

-

Vertical KilnLearn More

Vertical kilns are primarily used for roasting bauxite. Roasting involves heating bauxite to high temperatures to change its chemical composition and convert it into alumina. This process is a crucial step in aluminum production.

-

Reverberatory FurnaceLearn More

Reverberatory furnaces are mainly used for melting aluminum ingots and casting aluminum alloys. The furnace produces high temperatures through fuel combustion or electric heating, melting the aluminum ingots for subsequent casting and processing.

-

Electrolytic CellLearn More

Electrolytic cells are the core equipment in the aluminum electrolysis process. In the electrolytic cell, alumina undergoes electrolytic reactions in a high-temperature electrolyte to produce aluminum.