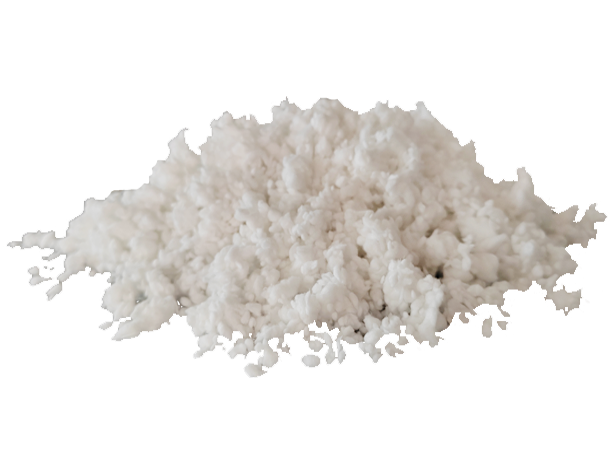

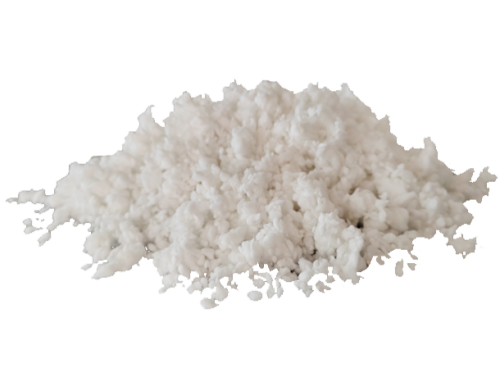

CCEWOOL® Ceramic Fiber Friction Bulk features excellent friction properties, wear resistance, and low dust emissions, and is widely used in braking systems, clutches, and other friction applications.

Get a Quote-

Enhanced Performance by Mixing Ceramic Fibers with Binders

This product combines ceramic fibers with organic and inorganic binders, improving overall performance and enhancing stability and durability.

-

Excellent Friction Performance with Low Dust Emission

Offering superior friction and wear resistance, the material produces minimal dust during use, ensuring a clean and eco-friendly application.

-

Silent Operation for Noise and Vibration Reduction

Nearly silent during operation, it is an ideal material for noise and vibration reduction, providing a quiet and efficient working environment.

-

Widely Used in Braking and Friction Systems

The product is extensively used in braking systems, clutches, and other friction applications, valued for its excellent friction and wear resistance.