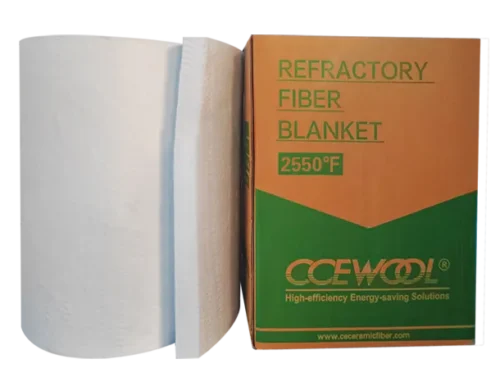

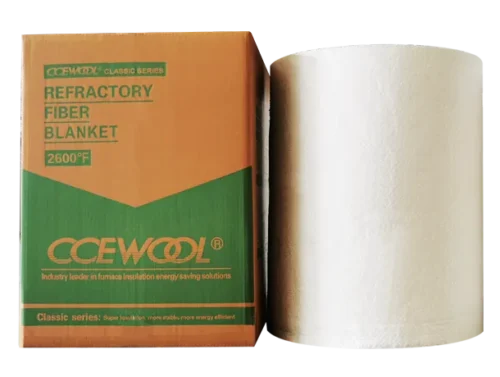

CCEWOOL® Ceramic Fiber Blanket S 2300 features controllable density and high elasticity, with a tensile strength exceeding 75 KPa, ensuring high strength and durability. Reach Registration Certificate will be provided as requested for each shipment.

Get a Quote-

High Efficiency and Energy Saving, Suitable for Harsh Environments

The product is lightweight, strong, and easy to install, with low thermal conductivity and excellent heat storage capacity, effectively conserving energy. It also features good thermal shock resistance, making it ideal for various harsh environments.

-

Strict Impurity Control, Stable and Reliable Quality

With strict raw material management, impurity content is reduced to below 1%. At the highest continuous operating temperature, the shrinkage rate remains below 3%, ensuring more stable product quality.

-

Outstanding Thermal Performance with Low Slag Ball Content

With slag ball content below 15%, the product performs exceptionally in continuous high-temperature environments, offering low thermal conductivity and excellent insulation performance.

-

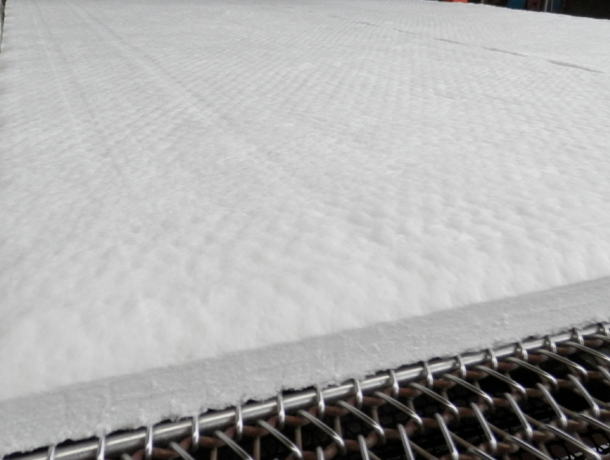

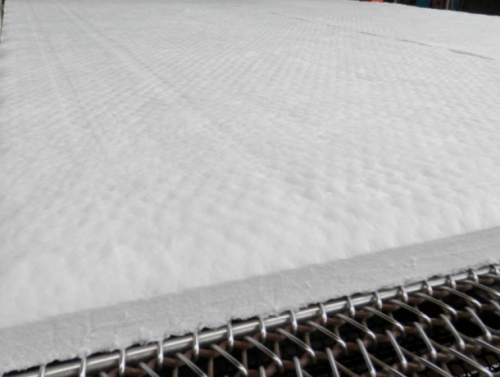

Innovative Needling Technology for Enhanced Tensile Strength

Using a proprietary double-sided needling process with internal needle patterns, the product achieves tensile strength exceeding 75 KPa, effectively resisting impact in harsh environments and extending its service life.