What’s the difference between ceramic fiber board and bio soluble fiber board?

- 16 Jul, 2025

- Industry

In the selection of high-temperature insulation materials, ceramic fiber board is widely used in industrial furnaces, thermal processing equipment, and heat-resistant structural applications due to its excellent thermal resistance and mechanical strength. However, with increasingly stringent environmental regulations and growing demand for health and safety, bio soluble fiber board is emerging as a more eco-friendly and safer alternative.

So, what's the difference between a ceramic fiber board and a bio soluble fiber board, and what unique advantages does the latter bring to high-temperature applications?

Material Upgrade – More Eco-Friendly and Safer

Traditional ceramic fiber board is mainly composed of high-purity alumina and silica, offering excellent heat resistance. However, its fibers are biologically persistent and difficult for the human body to break down naturally, posing potential long-term health risks. This has led to growing restrictions on its use in markets such as the EU and North America.

In contrast, CCEWOOL® bio soluble fiber board is formulated with low bio-persistent (LBP) materials, based on alkaline earth silicate compositions (AES). These fibers dissolve and are metabolized naturally by the human body shortly after inhalation, significantly reducing health hazards. The product has passed the solubility test certification of the German Fraunhofer laboratory, making it especially suitable for industries with high environmental and health standards—such as food processing, household appliances, and pharmaceuticals.

Stable Performance – Strength with Flexibility

While maintaining strong thermal insulation properties, CCEWOOL® bio soluble fiber board also offers excellent thermal shock resistance and mechanical stability. Compared to traditional ceramic fiber boards, it is more flexible and less brittle, making it ideal for environments with complex installation conditions and frequent thermal cycling, thus extending service life.

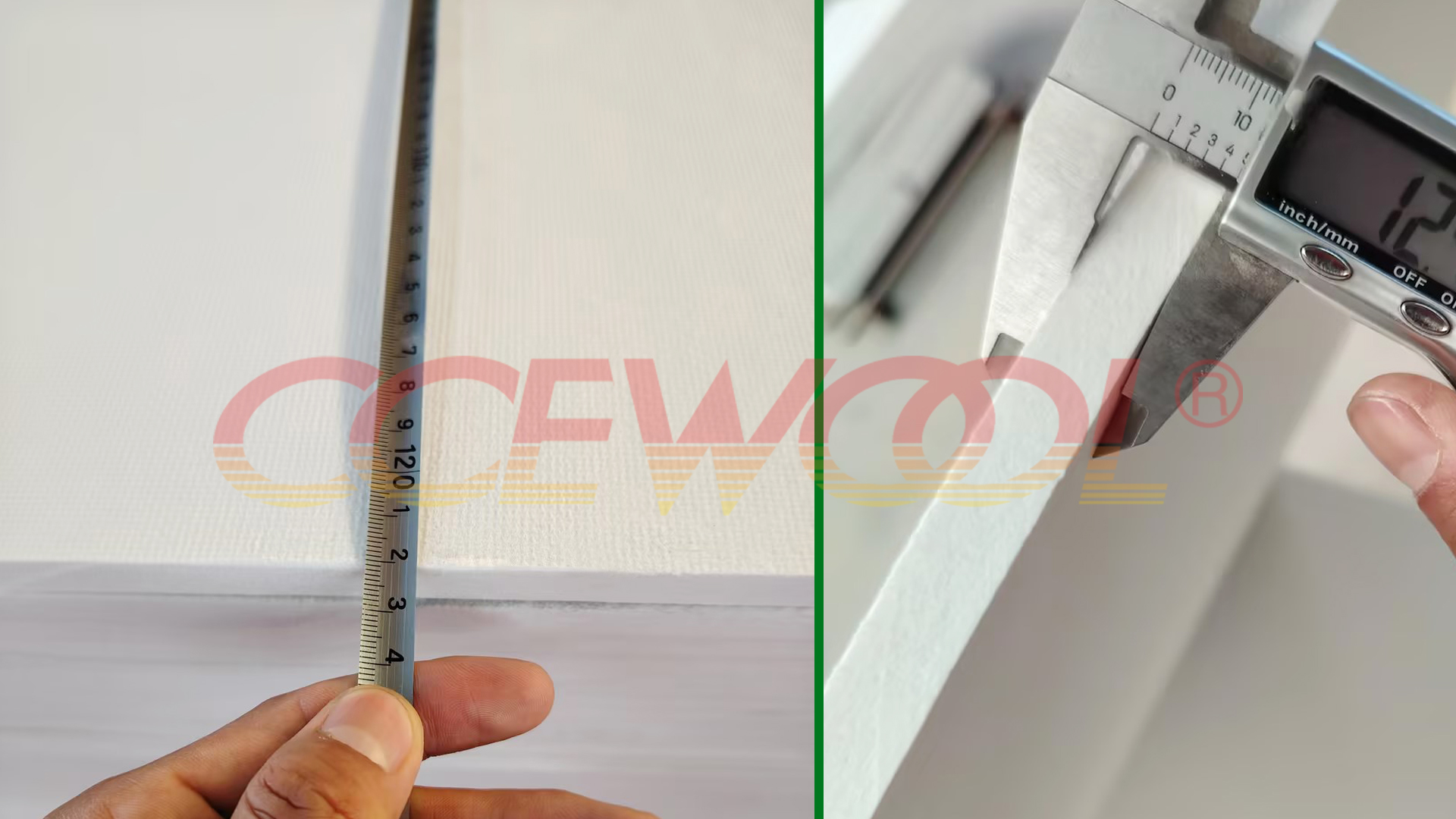

With a uniform internal structure and clean edges, the board is easy to cut and shape, making it well-suited for precision applications such as shaped components, furnace doors, and high-temperature seals.

If you're looking for an insulation board that delivers both excellent thermal performance and superior environmental and health safety, CCEWOOL® bio soluble fiber board is clearly the better choice.