What does a ceramic blanket do?

- 04 Dec, 2024

- Industry

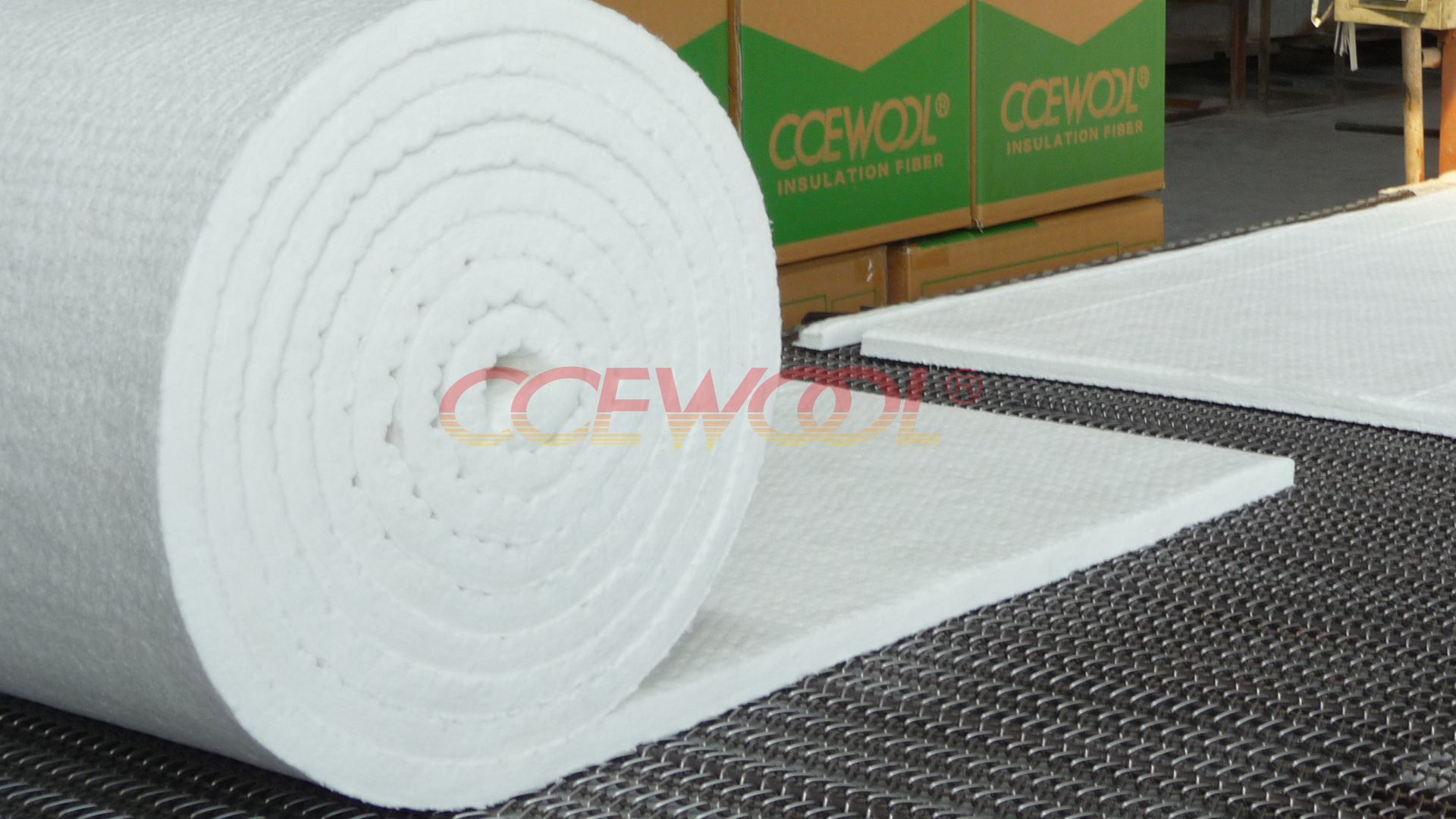

Ceramic blankets are highly efficient high-temperature insulation materials that play a vital role across numerous industries. CCEWOOL® ceramic blankets, with their exceptional thermal performance and outstanding mechanical strength, provide reliable insulation protection for a variety of complex high-temperature applications.

The core value of CCEWOOL® ceramic blankets lies in their exceptional thermal insulation performance. With low thermal conductivity and low heat storage capacity, they effectively reduce heat transfer, thereby lowering energy consumption, making them an ideal choice for industrial furnace linings and high-temperature equipment insulation. Moreover, these blankets can withstand extreme temperatures up to 1430°C, maintaining stable insulation performance even in harsh environments and providing long-lasting protection for equipment.

In addition, CCEWOOL® ceramic blankets excel in flexibility and tensile strength. They adapt to the installation requirements of equipment with complex shapes and, thanks to their excellent thermal shock resistance, are not prone to cracking due to rapid temperature changes. This makes them not only widely used in traditional industrial fields but also the ideal material for insulation protection in precision industries such as aerospace and automotive manufacturing.

With their outstanding thermal insulation and superior mechanical properties, CCEWOOL® ceramic blankets are the top choice for high-temperature environments. They meet the demands of various complex application scenarios and demonstrate reliable performance advantages across multiple industries.