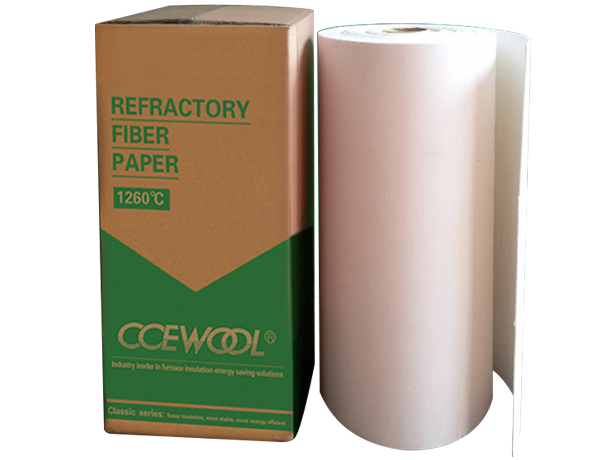

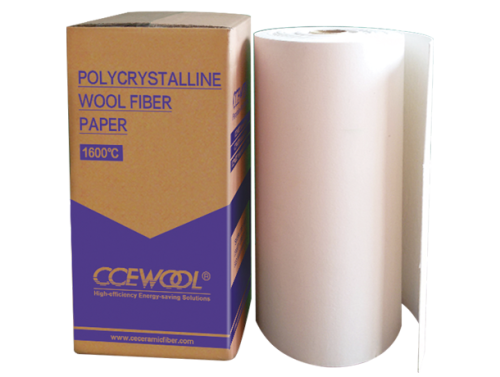

CCEWOOL® Ceramic Fiber Paper is characterized by high temperature resistance and chemical stability. It is mainly used for insulation and heat preservation in high-temperature environments.

Get a Quote-

Nine-Step Slag Removal Process for Premium Quality

Refined through a nine-step slag removal process, this product ensures high purity and stable performance, excelling in high-temperature applications.

-

High-Temperature Resistance and Excellent Corrosion Resistance

Capable of withstanding temperatures exceeding 1000°C, it offers exceptional chemical stability and effective resistance to acidic and alkaline corrosion, making it suitable for harsh chemical environments.

-

Outstanding Insulation and Processing Performance

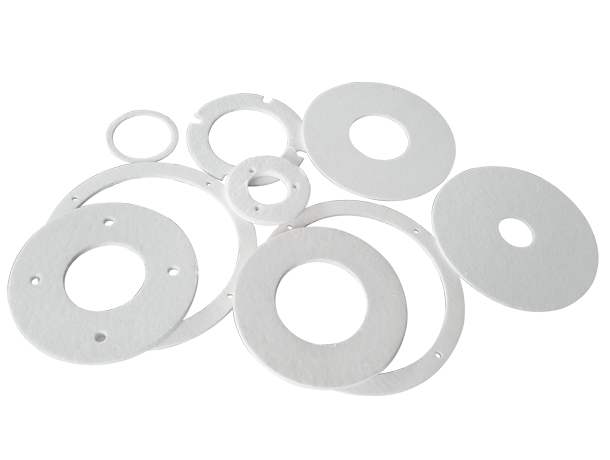

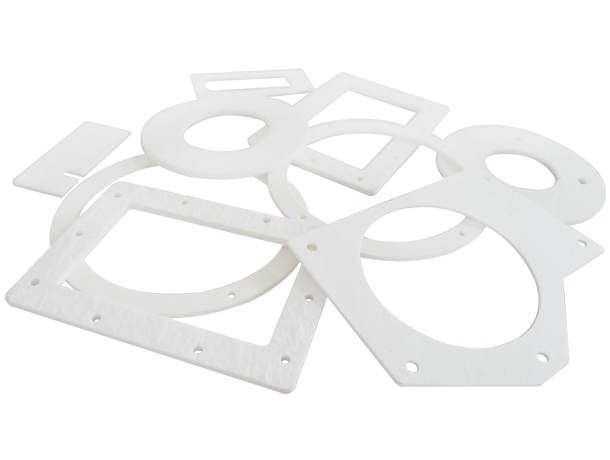

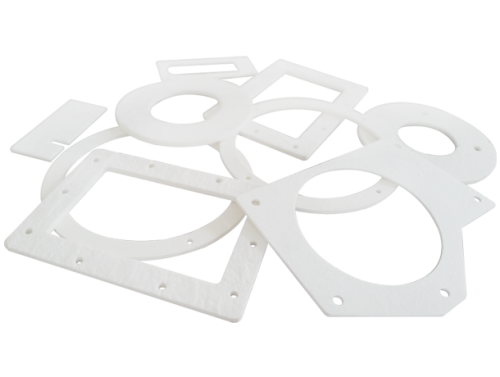

With superior insulation and workability, it supports advanced processing such as multi-layer lamination and die-cutting. It is ideal for applications in thermal insulation, sealing, electrical insulation, sound absorption, and filtration under high temperatures.

-

Excellent Electrical Insulation and Mechanical Strength

Featuring reliable electrical insulation and mechanical strength, it performs consistently in high-temperature environments, meeting demanding operational requirements.