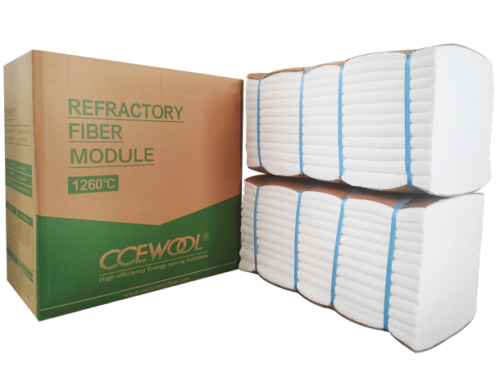

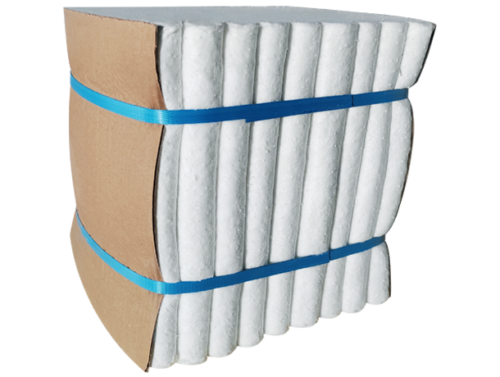

CCEWOOL® Ceramic Fiber Module is resistant to high temperatures and has high strength, making it ideal for insulation and heat preservation under extreme high-temperature conditions.

Get a Quote-

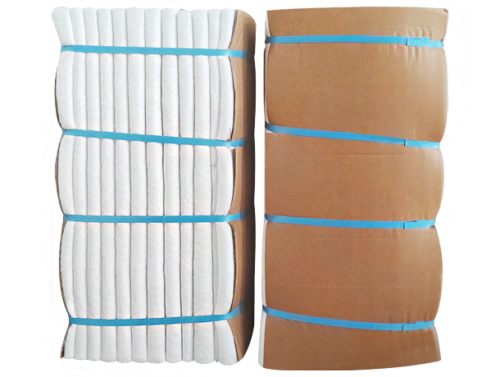

Made from Spun Ceramic Fiber Blanket, Fully Customizable

This product is made from spun ceramic fiber blankets and is precisely machined to meet customer-specific requirements based on drawings, ensuring compatibility with specialized applications.

-

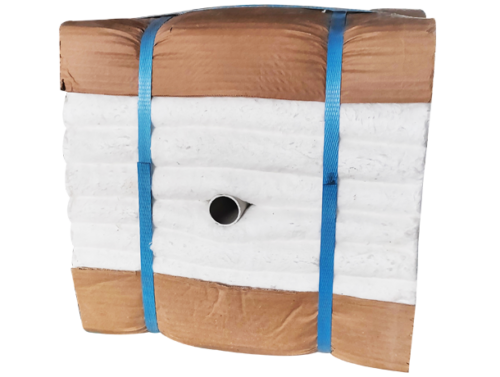

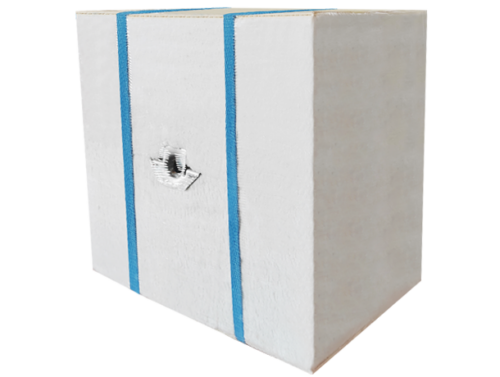

Precisely Sized for Direct Fixation on Furnace Anchors

With accurate dimensions, the modules can be directly fixed onto anchor studs on industrial furnace steel shells, offering excellent refractory insulation and enhancing overall furnace insulation performance.

-

Modular Design, Adaptable to Various Furnace Types

The modules can be customized to different furnace types and specifications, ensuring perfect compatibility with equipment.

-

Custom Shaped Modules for Special Applications

In addition to standard modules, we also provide custom-shaped modules tailored to meet unique customer requirements, offering optimal solutions for complex operating conditions.