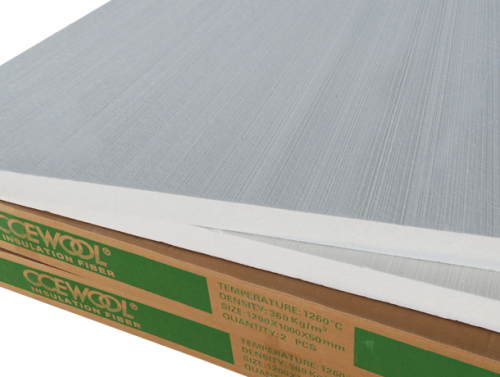

CCEWOOL® Ceramic Fiber Board RG 2300 is suitable for applications requiring high rigidity and strength, with high resistance to fracture, compressive strength, wear resistance, and resistance to hot gas erosion.

Get a Quote-

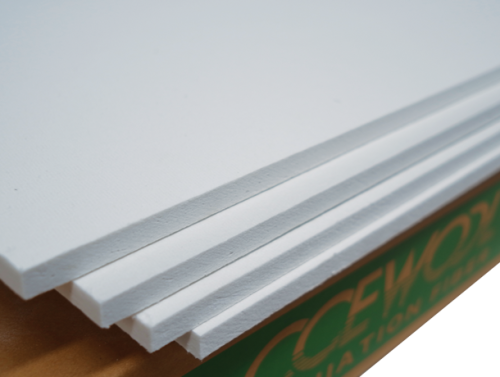

Cost-Effective Insulation Board with Surface Hardening for Enhanced Strength

This insulation board offers cost-efficiency with a hardened surface treated with a coating and drying process, exhibiting excellent rigidity, ideal for applications requiring high surface strength.

-

High Fracture and Compressive Strength for Demanding Environments

Designed for industrial applications with high-strength requirements, the board provides outstanding fracture resistance, compressive strength, and wear resistance while withstanding hot gas erosion.

-

An Excellent Alternative to Refractory Materials for the Glass Industry

The board is particularly suited as an alternative to dense refractory materials and finds broad application in the glass industry and other fields with high refractory demands, offering robust support.

-

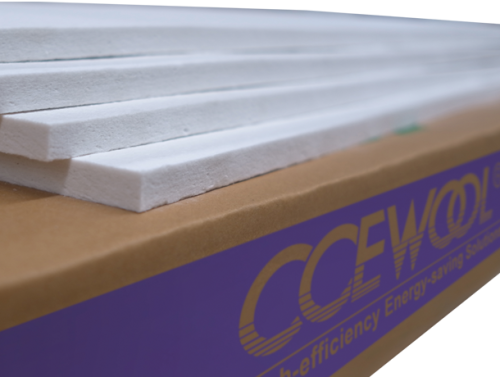

Rigid Surface Protection to Minimize Dust Pollution

Serving as a protective hot-face layer over blanket linings, its rigid surface effectively suppresses dust during installation and operation, enhancing environmental cleanliness during use.