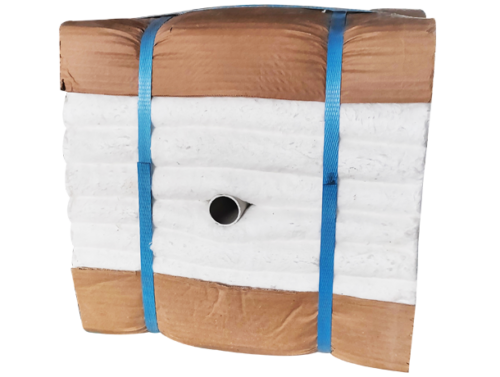

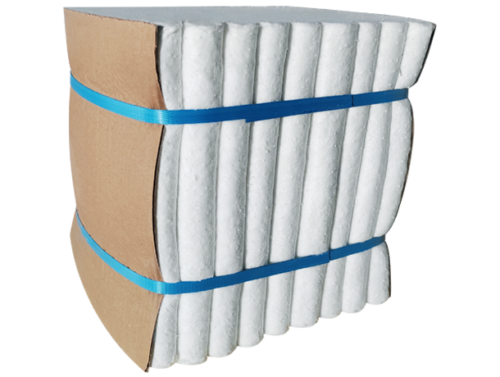

CCEWOOL® Polycrystalline Wool Fiber Module HD 2912 has high corrosion resistance, making it suitable for insulation in corrosive environments. It has a relatively high classification temperature.

Get a Quote-

Fiber Module Designed for 1300°C to 1500°C High-Temperature Insulation

Specifically designed for full-fiber linings, this module provides durable high-temperature protection between 1300°C (2372°F) and 1500°C (2732°F).

-

Outstanding Thermal Stability and Thermal Shock Resistance

This product features excellent thermal stability and resistance to thermal shock, maintaining its integrity even in extreme high-temperature environments, ensuring safety and durability.

-

Low Thermal Conductivity and High Mechanical Strength

With low thermal conductivity for superior insulation and high mechanical strength, the fiber module is easy to process and customize to meet diverse needs.

-

Composite Module Solutions

We offer composite modules made from CCEWOOL® Polycrystalline Fiber Blanket and CCEWOOL® RCF Blanket 2600, meeting temperature requirements while helping customers save on costs.