CCEWOOL® M110 Microporous Insulation Board is the ideal material for reducing heat loss and improving energy efficiency, making it an excellent choice for lightweight and energy-saving applications in kilns and other high-temperature environments.

Get a Quote-

Superior Thermal Conductivity at Low Temperatures

With a thermal conductivity lower than that of static air, it effectively saves space, weight, and energy.

-

Outstanding Insulation Performance at High Temperatures

Its thermal conductivity changes minimally with rising temperatures, offering 3-4 times better insulation than traditional materials in high-temperature environments.

-

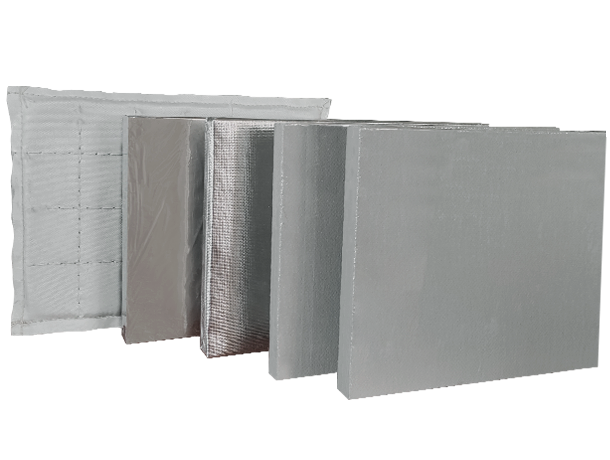

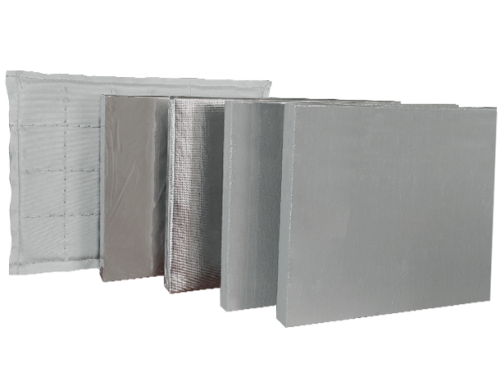

Optional Surface Protection for Enhanced Durability

Available with protective layers such as aluminum foil or fiberglass cloth to reduce dust, enhance strength, and protect against moisture damage.

-

The Ideal Choice for High-Temperature Insulation

As the most efficient high-temperature solid insulation material, it is perfect for lightweight and energy-saving applications in furnaces.