Is ceramic fiber flammable?

- 24 Jul, 2024

- Industry

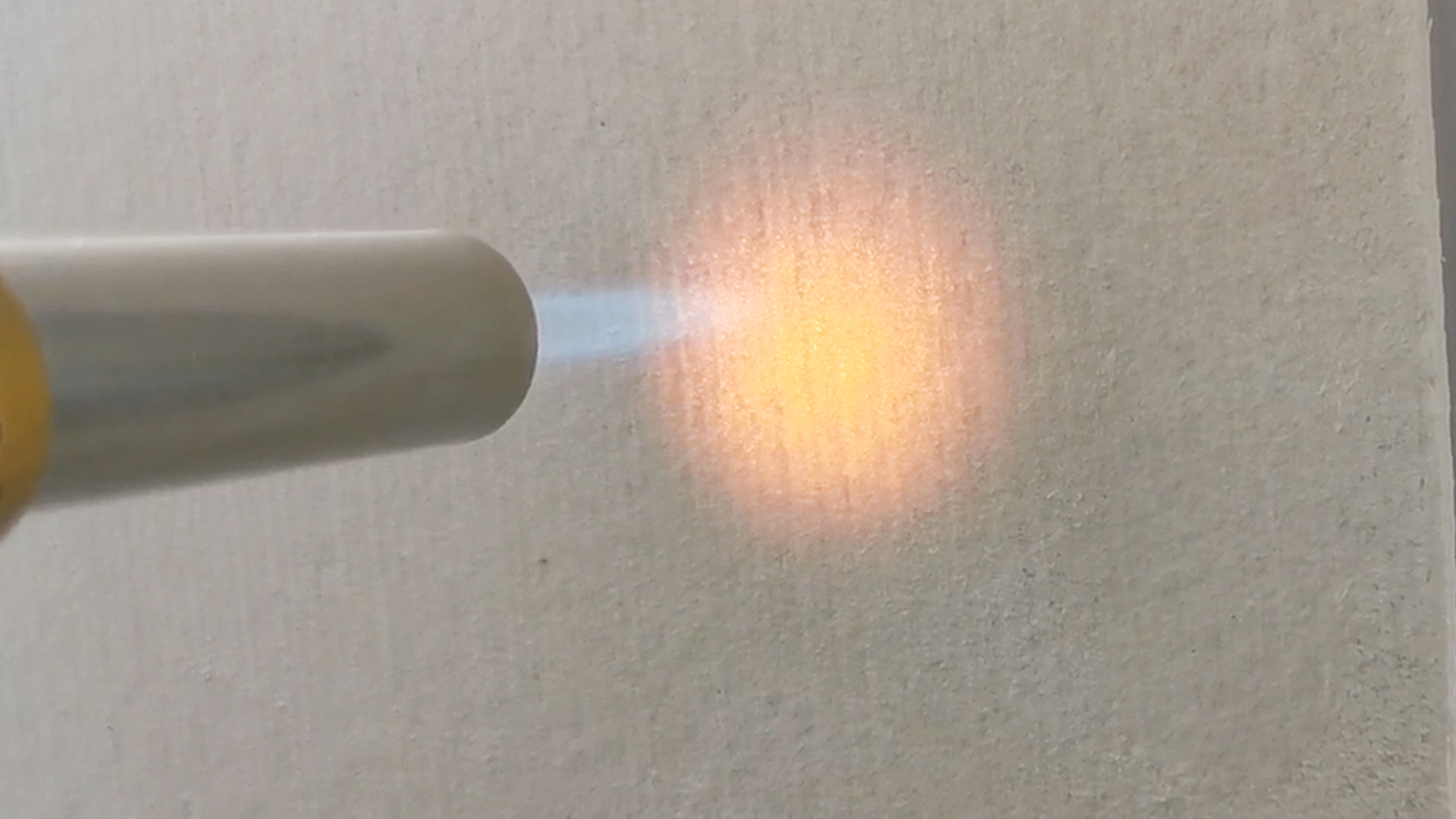

In the industrial field, safety is one of the primary considerations, especially when it comes to high-temperature operations. The fire resistance of materials becomes particularly crucial. Many might wonder: are ceramic fibers flammable? The answer is no. CCEWOOL® ceramic fiber products, with their excellent high-temperature resistance and fireproof performance, stand out as top choices among industrial insulation materials.

Ceramic fiber is an inorganic fiber material composed of high-purity alumina and silica. It features light weight, high strength, high-temperature resistance, low thermal conductivity, and other excellent characteristics. CCEWOOL® ceramic fiber products include ceramic fiber blankets, ceramic fiber boards, and ceramic fiber paper, which are widely used for the insulation and fireproofing needs of various high-temperature industrial equipment.

Advantages of CCEWOOL® Ceramic Fiber Products

Outstanding High-Temperature Resistance:

CCEWOOL® ceramic fiber products remain stable at extremely high temperatures without decomposing or burning. With a maximum service temperature of up to 1400°C, they are suitable for various high-temperature industrial equipment such as furnaces, kilns, and boilers.

Excellent Fireproof Performance:

Ceramic fiber is an inorganic material that does not burn and does not produce harmful gases. This makes CCEWOOL® ceramic fiber products crucial in providing insulation and fireproofing during a fire, ensuring the safety of equipment and personnel.

Low Thermal Conductivity:

CCEWOOL® ceramic fiber products have low thermal conductivity, effectively reducing heat loss and improving energy efficiency. This helps lower industrial production costs and reduces energy consumption, which is beneficial for environmental protection.

Chemical Corrosion Resistance:

CCEWOOL® ceramic fiber products are highly resistant to most chemicals and are not easily corroded by acids and alkalis, extending the material's service life and reducing maintenance costs.

Lightweight and High Strength, Easy to Install:

The material is lightweight and flexible, easy to cut and install, and can be customized according to specific needs, reducing construction difficulty and improving efficiency.

Application Fields

Due to their excellent high-temperature and fireproof performance, CCEWOOL® ceramic fiber products are widely used in the petrochemical, power, metallurgy, and construction industries for high-temperature equipment and fireproof insulation systems. Whether it is for the lining of high-temperature furnaces or fireproof partitions in buildings, CCEWOOL® ceramic fiber products provide reliable solutions.

With their outstanding high-temperature resistance, fireproofing, and insulation properties, CCEWOOL® ceramic fiber products have become the ideal choice in the high-temperature industrial field. They not only provide reliable fireproofing and insulation in harsh environments but also improve the operational efficiency of equipment, extend its service life, and reduce maintenance costs.