High Temperature Ceramic Insulation Blanket – CCEWOOL®

- 24 Feb, 2025

- Insight

In high-temperature applications, the performance of fireproof fiber blankets directly determines insulation effectiveness, energy efficiency, and equipment stability. The content of slag balls is a key factor affecting the thermal conductivity, insulation performance, and long-term stability of fireproof fiber blankets. Slag balls are glass particles that have not fully converted into fibers during production. An excessively high slag ball content can lead to reduced insulation performance, weakened mechanical strength, shortened service life, and even increase construction difficulty and safety hazards. Therefore, strictly controlling the slag ball content is crucial for high-quality, high-performance high temperature ceramic insulation blankets.

To ensure the excellent performance of high temperature ceramic insulation blankets in high-temperature environments, CCEWOOL® adopts advanced production equipment, unique manufacturing processes, and patented low-slag ball technology to strictly control slag ball content from the source. Specific measures include:

High-temperature resistance furnace smelting: Using high-quality raw materials, we fully melt them in a 2000-2200°C resistance furnace to ensure the purity of the raw materials and minimize slag ball generation.

High-efficiency centrifugal technology: Using imported high-speed centrifuges with a rotational speed of up to 11,000 revolutions per minute, significantly increasing the fiber yield, ensuring fiber uniformity, and greatly reducing the production of slag balls.

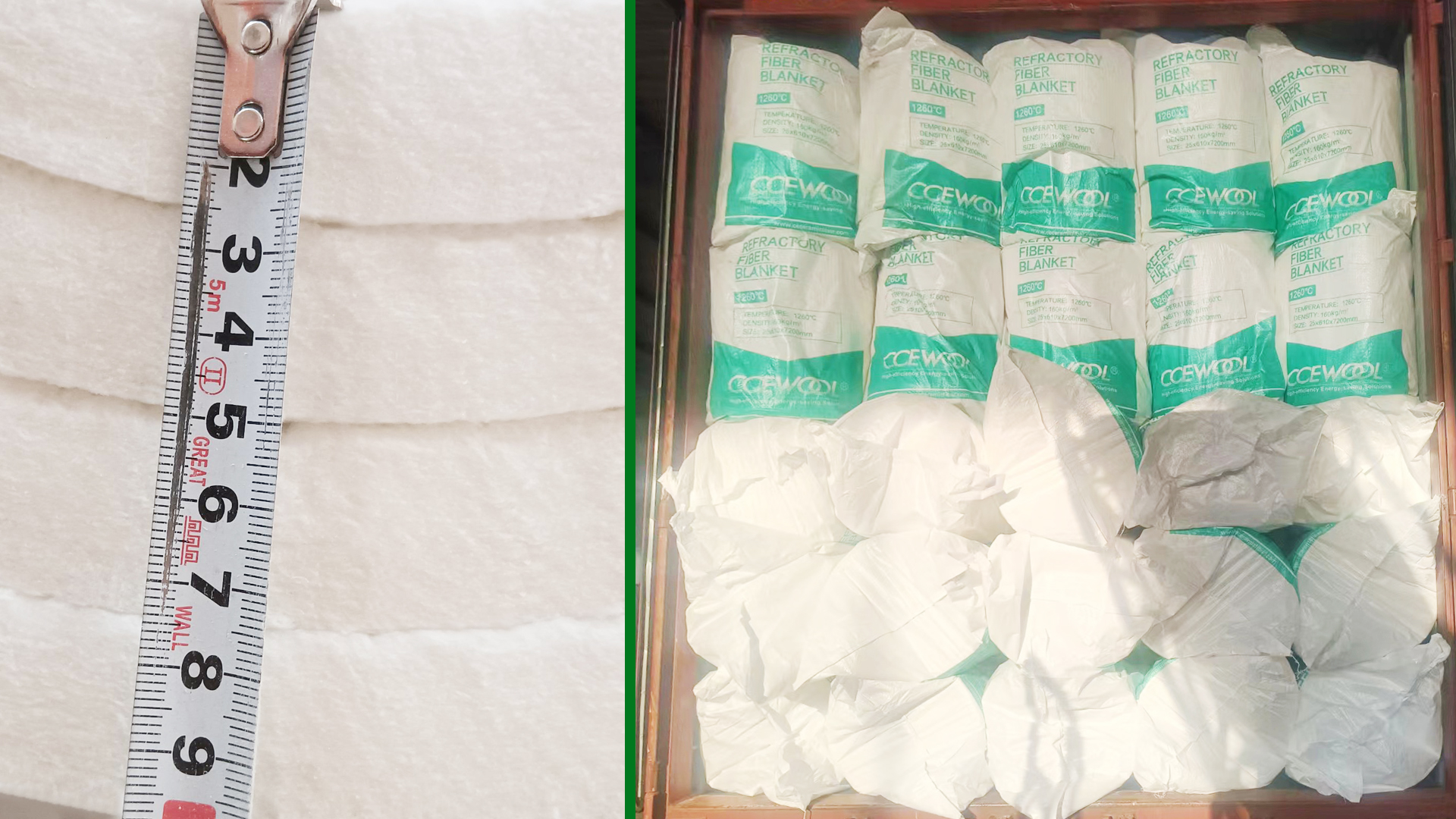

Indonesia Customer

Cooperation years: 6 years

Ordered product: CCEWOOL® high temperature ceramic insulation blanket

Product size: 25x610x7200mm

We recently customized a batch of CCEWOOL® high temperature ceramic insulation blanket for our client in Indonesia, with specifications of 25x610x7200mm. The client highly praised the high purity, excellent insulation performance, and low slag ball content of our product. They especially recognized our production processes and slag ball control technology, believing that it significantly improved the reliability and service life of the product.