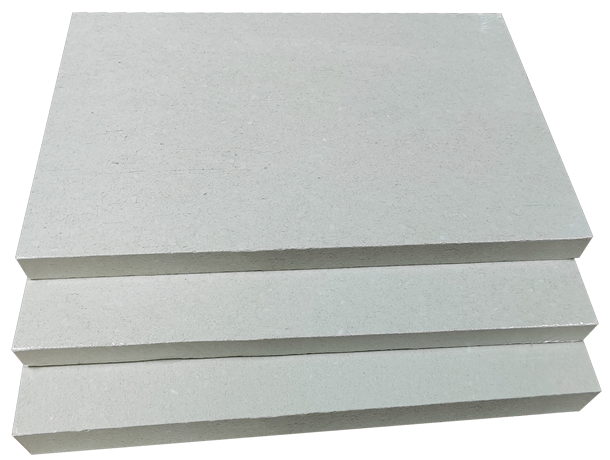

CCEWOOL® Super Duty Ceramic Fiber Board is tough, with a normal temperature bearing capacity greater than 80t/m² and a high-temperature bearing capacity greater than 40t/m². Its compressive strength is several times higher than that of standard refractory ceramic fiber boards.

Get a Quote-

Advanced Fire-Resistant Insulation Material with Exceptional High-Temperature Performance

This new fire-resistant insulation material maintains high strength and low thermal conductivity under high-temperature conditions, providing reliable insulation protection in various demanding environments.

-

Compressive Strength Ten Times Higher than Standard Ceramic Fiber Boards

Its compressive strength exceeds that of typical ceramic fiber boards by over tenfold, while delivering comparable insulation performance to traditional ceramic fiber boards.

-

Efficient Drying for Consistent Quality

Using a fully automated drying system, the product undergoes deep, uniform drying within two hours, ensuring compressive and flexural strengths above 1.2 MPa, enhancing overall quality and durability.

-

Precision CNC Cutting for High Accuracy

With fully automated CNC machinery, the product is cut with near-zero dimensional error, meeting the stringent requirements of high-precision applications.