CCEWOOL rock wool insulation blanket

- 19 Jun, 2024

- Insight

Peruvian Customer

Cooperation years: 7 years

Ordered product: CCEWOOL rock wool insulation blanket

Product size: 50x600x1200mm

The shipment of three containers of CCEWOOL rock wool insulation blankets ordered by our customer in Peru, with dimensions of 50x600x1200 mm and densities of 60 kg/m³ and 100 kg/m³, has been dispatched on time from the factory on March 18, 2024, and is now in transit. Please note the delivery.

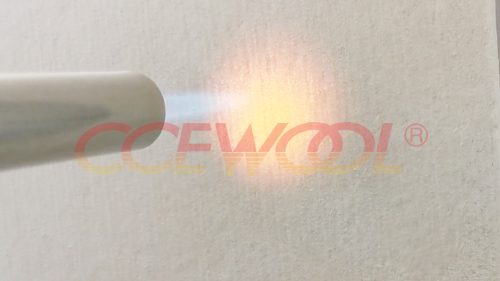

CCEWOOL rock wool insulation blankets are made from high-quality natural basalt, a renewable resource. These rock wool blankets are not only environmentally friendly but also maintain their quality even when recycled. CCEWOOL has specialized in the rock wool insulation field for 20 years, focusing on research and development of energy-saving solutions. We professionally produce and provide rock wool products that are fire-resistant, highly efficient in thermal performance, and capable of withstanding high temperatures, ensuring that customers receive high-performance insulation materials.

This customer has maintained a long-term partnership with CCEWOOL and has been consistently purchasing CCEWOOL rock wool insulation blankets and other products. The customer has always trusted the quality of CCEWOOL's products and services, and our cooperation has been very pleasant.

The containers carrying the CCEWOOL rock wool insulation blankets are expected to arrive at the destination port around April 20th. Customers are advised to make preparations in advance to receive the goods, ensuring that the products can be put to use promptly. We appreciate the customer's continued support and trust, and we look forward to continuing to provide excellent products and services, helping the customer's projects achieve even greater success.