What is the use of ceramic fiber cloth?

- 28 May, 2025

- Industry

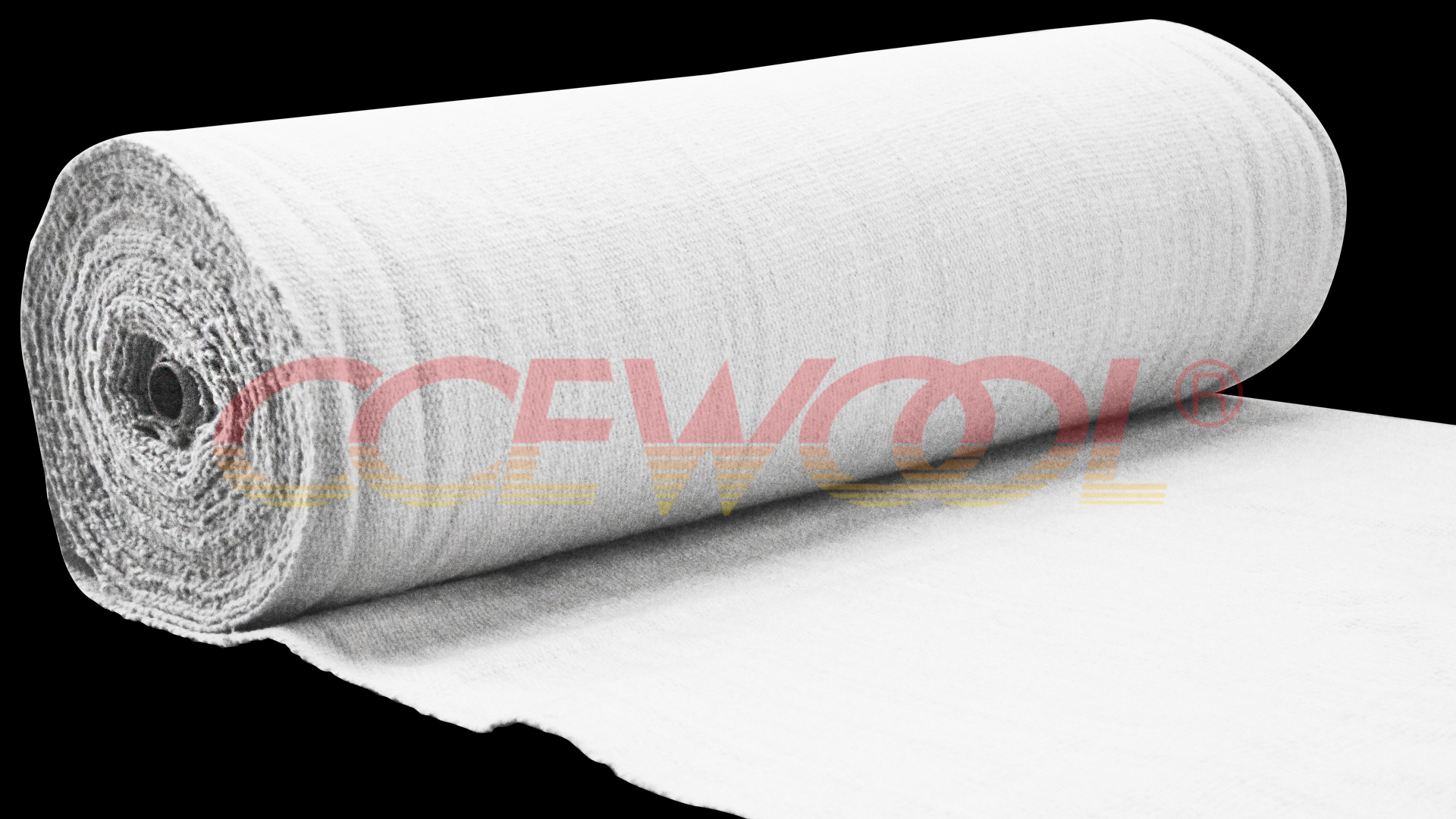

In modern high-temperature industrial applications, the performance of insulation, protection, and sealing materials directly affects the safety and stability of equipment operations. Among these materials, ceramic fiber cloth stands out with its excellent thermal resistance, flexibility, and mechanical strength, making it an essential high-temperature protection material in various thermal equipment.

What is ceramic fiber cloth?

Ceramic fiber cloth is a flexible woven material made from high-purity ceramic fibers. It is often reinforced with fiberglass or stainless steel wire to enhance tensile strength and abrasion resistance. Ceramic fiber cloth can withstand continuous high temperatures while maintaining flexibility and cuttability, making it widely used for insulation, wrapping, and protection in high-temperature environments.

Typical applications of ceramic fiber cloth:

🔸 Thermal insulation wrapping for high-temperature equipment

Used on heaters, reactors, pipes, valves, and other equipment surfaces to reduce heat loss and improve energy efficiency.

🔸 Flexible fire curtains or heat shields

Ideal for steel, glass, metallurgy industries—used around furnace doors or heat zones as movable fire barriers or thermal dividers.

🔸 High-temperature sealing tapes and gaskets

Can be processed into sealing strips or gaskets for ducts, flanges, and furnace seams to prevent hot air or gas leaks and improve system sealing.

🔸 Thermal protection for cables and pipelines

In aerospace, automotive, and shipbuilding industries, ceramic fiber cloth is used to wrap cables and hoses, protecting them from flames or high heat.

🔸 Flexible expansion joint material

Used in environments with frequent thermal expansion or vibration, ceramic fiber cloth serves as an inner lining for compensators, absorbing structural shifts and thermal stress.

Whether for insulation, heat shielding, or sealing applications, CCEWOOL® ceramic fiber cloth has proven to be a reliable choice across industries. Choosing CCEWOOL® means choosing a high-performance, heat-resistant, corrosion-resistant, and flexible ceramic fiber cloth—ensuring long-term safety and efficiency in your high-temperature operations.