What is ceramic insulation board used for?

- 27 Aug, 2025

- Industry

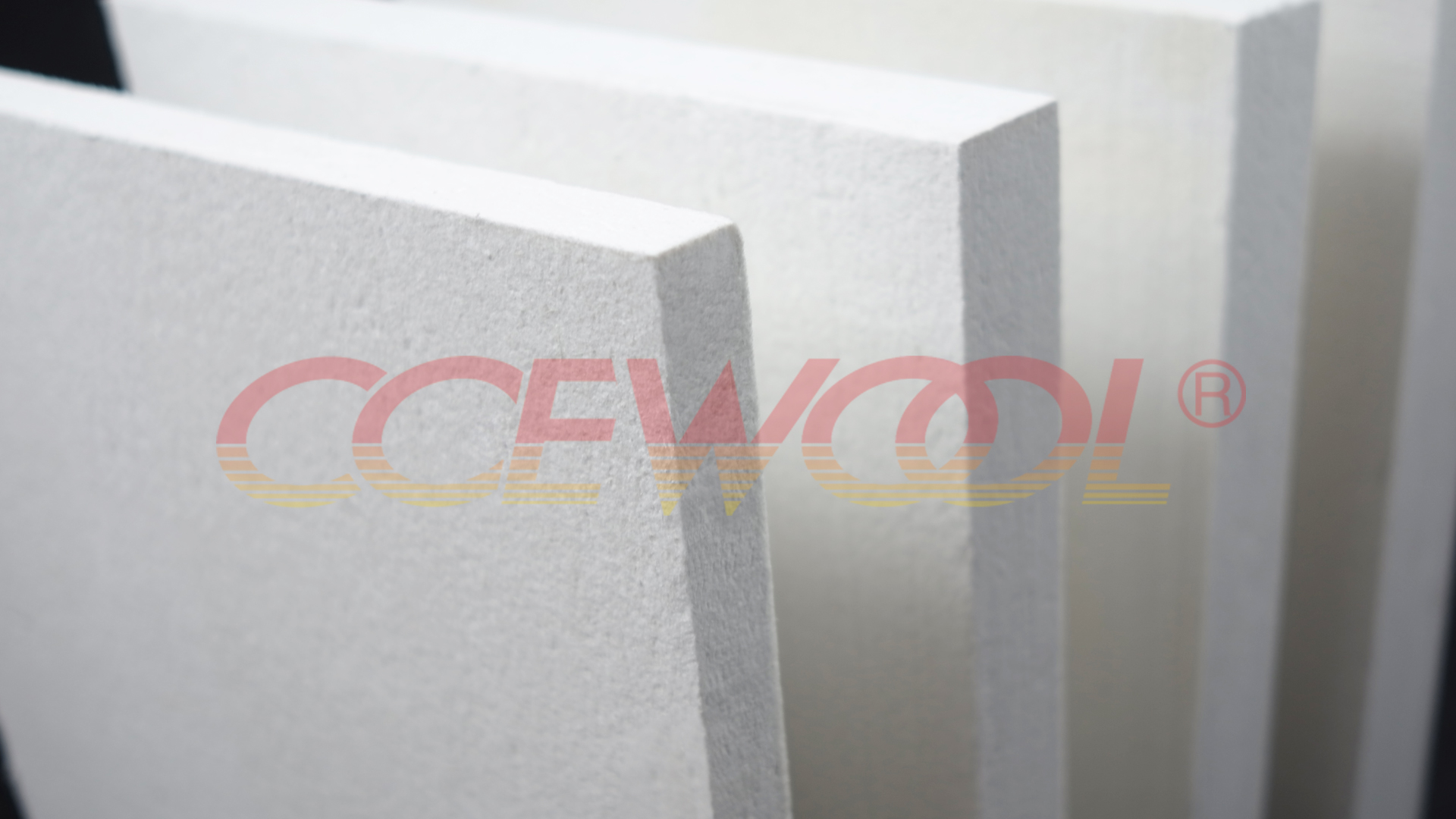

CCEWOOL® Ceramic insulation board is a lightweight, high-temperature insulation material widely used in industries such as metallurgy, petrochemicals, glass, ceramics, heat treatment, electronics, and power generation. It is commonly applied as furnace linings, back-up insulation layers, high-temperature duct insulation, and hot-face or back-up protection layers. It is also widely used in laboratory furnaces, industrial kilns, heat treatment furnaces, and other high-temperature equipment. With excellent insulation performance and structural stability, it has become an ideal alternative to traditional refractory bricks and insulating bricks.

Unique Advantages of CCEWOOL® Ceramic Insulation Board

Compared with traditional insulation materials, CCEWOOL® ceramic insulation boards have several distinct advantages:

Low thermal conductivity: Maintains excellent insulation performance even at high temperatures, effectively reducing energy loss.

High strength and stability: Resists powdering and cracking, ensuring long-term structural integrity.

Superior thermal shock resistance: Withstands frequent heating and cooling cycles, adapting to complex operating conditions.

Lightweight and easy to process: Easy to cut, install, and apply modularly, suitable for irregular or complex equipment structures.

Clean and environmentally friendly: Inorganic-bonded types release no smoke or odor at high temperatures, making them suitable for industries requiring clean environments.

In glass melting furnaces, steel heat treatment furnaces, aluminum electrolytic cells, and petrochemical heating furnaces, using ceramic insulation boards as insulation layers can significantly reduce heat loss, lower furnace shell temperature, and extend lining life. This reduces maintenance frequency and downtime, improving energy efficiency while lowering operating costs. For enterprises, this also enhances production continuity and overall safety.

In summary, CCEWOOL® ceramic insulation board plays an important role in high-temperature industries. It is not only an efficient insulation material but also a key solution for improving thermal efficiency and ensuring stable operation of equipment. With the growing demand for energy saving and environmental protection in high-temperature industries, the applications of ceramic insulation boards will continue to expand, making them one of the preferred materials for global high-temperature insulation systems.