Superwool Insulation Blanket – CCEWOOL®

- 01 Sep, 2025

- Insight

In the European market, insulation materials for high-temperature applications must not only deliver performance but also comply with increasingly strict environmental and safety regulations. Traditional ceramic fiber blankets, due to their higher biopersistence, often require carcinogen warning labels, creating compliance and application challenges for customers. The industry urgently needs a material that provides both high thermal insulation and compliance with safety and environmental standards.

Product Advantage: Solubility Certification + No Warning Labels

CCEWOOL® Superwool Insulation Blanket is made from low bio-persistent (LBP) fibers, which are soluble and biodegradable in body fluids. It has been certified by Fraunhofer Laboratory in Germany for its solubility performance and fully meets the Globally Harmonized System (GHS) standards. Its biodegradability and safety are scientifically validated, meaning the product can be used without carcinogen warning labels in the EU and other markets. This reduces compliance risks and highlights its environmentally friendly value.

Manufacturing Excellence: High-Purity Raw Materials + Fiber Spinning + Precision Needling

The unique performance of the CCEWOOL® Superwool Insulation Blanket is achieved through advanced manufacturing processes. Using proprietary formulations and high-purity raw materials, the fibers are melted and spun in electric furnaces, ensuring uniform diameter and low impurity content for better solubility. Automated layering and double-sided needling technology tightly interlock the fibers, giving the blanket excellent flexibility, durability, and resistance to erosion under high-temperature conditions.

Application Value: Combining Compliance, Safety, and High Performance

In boilers, heat treatment furnaces, glass kilns, and petrochemical equipment, the CCEWOOL® Superwool Insulation Blanket not only reduces heat loss and improves energy efficiency but also minimizes potential health risks due to its low biopersistence. Customers benefit from a high-performance insulation solution that meets EU regulations without additional warning labels or compliance burdens.

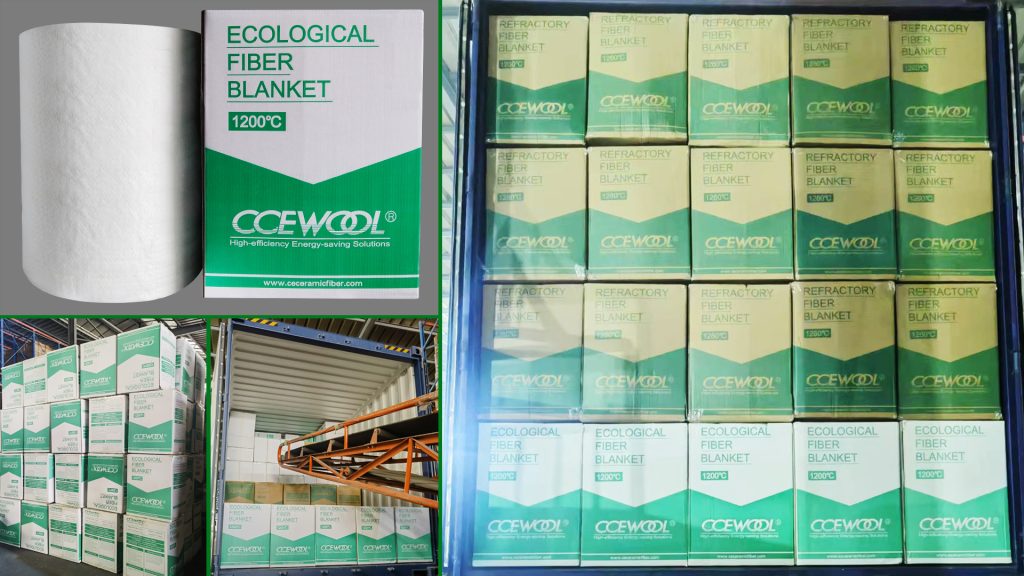

Polish Customer

Cooperation Years: 6 years

Ordered Product: CCEWOOL® Superwool Insulation Blanket and ceramic fiber blanket

Product Size: 25x610x7620mm / 25x610x3810mm

A long-term customer in Poland has been purchasing CCEWOOL® Superwool Insulation Blankets and ceramic fiber blankets since 2018, for six consecutive years. Their latest order included products sized 25x610x7620mm / 25x610x3810mm. The customer emphasized that CCEWOOL® blankets not only deliver stable performance but also meet strict EU compliance requirements. They also praised the fast delivery and professional service. With annual purchase volumes increasing, the partnership continues to deepen.

With certified solubility, proven safety, and compliance advantages, the CCEWOOL® Superwool Insulation Blanket has become a safer and more environmentally friendly choice in the global insulation market. Backed by advanced manufacturing processes and strict quality control, CCEWOOL® provides not only high-performance insulation solutions but also helps customers achieve both energy efficiency and regulatory compliance.