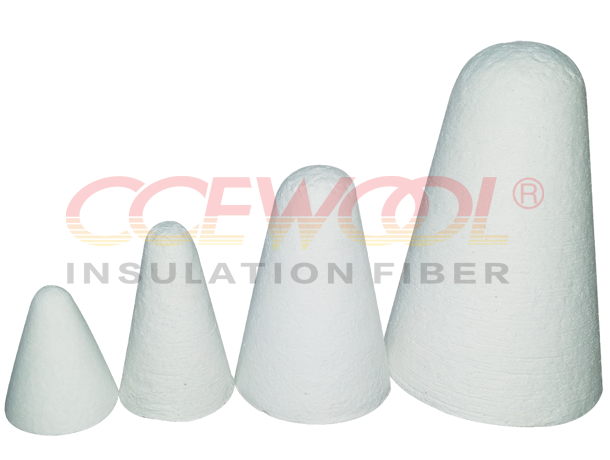

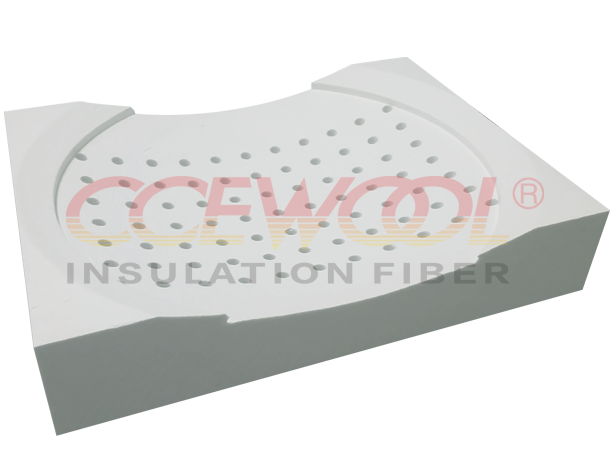

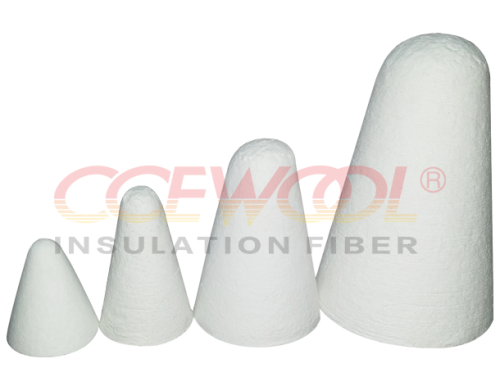

CCEWOOL® Low Biopersistent Fiber Shapes can be in direct contact with fire and can be customized into various shapes based on customer drawings. They feature extremely low thermal conductivity, low heat storage capacity, and good thermal shock resistance.

Get a Quote-

Environmentally Friendly and Biodegradable Fibers

Made from SiO₂, MgO, and CaO alkaline earth silicate (AES) components, these fibers are biodegradable, ensuring safety for human health and the environment.

-

Customized Shapes to Meet Specific Needs

Flexible manufacturing to produce products in various shapes based on customer-provided drawings, tailored to specific application requirements.

-

Low Thermal Conductivity and Excellent Thermal Shock Resistance

Features extremely low thermal conductivity, low heat storage capacity, and outstanding thermal shock resistance, ensuring efficient thermal insulation.

-

Exceptional Wear Resistance and Resistance to Molten Metals

Offers superior resistance to wear and spalling, with high resistance to wetting by most molten metals, making it suitable for demanding work environments.