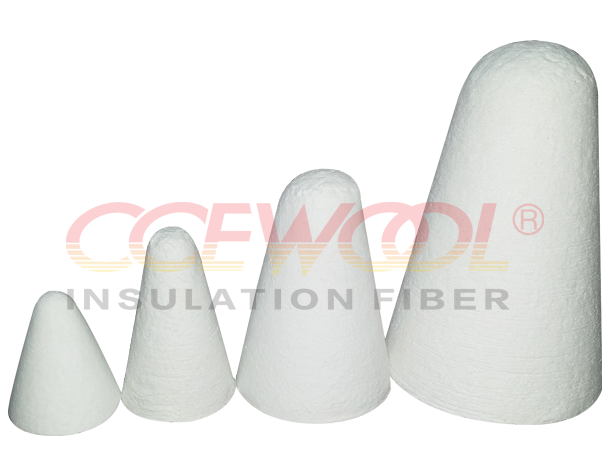

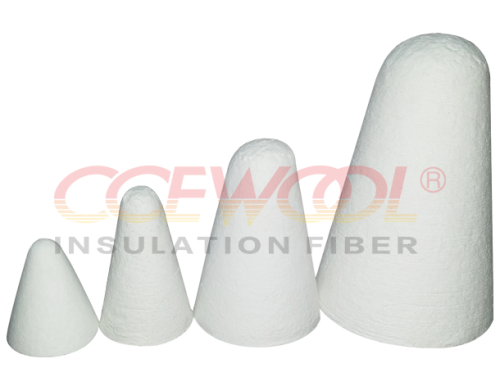

With its unique forming process and high-performance materials, CCEWOOL® HTIW Shapes offer an efficient thermal management solution for the aluminum casting industry.

Get a QuoteHighly efficient energy-saving solutions

Casting Molds: HTIW Shapes are used to create molds and cores for aluminum casting, offering excellent insulation to reduce energy consumption and ensure consistent mold temperatures.

Casting Ladles & Troughs: Used as linings in ladles and troughs, these shapes effectively protect the equipment from high temperatures and molten aluminum, extending service life.