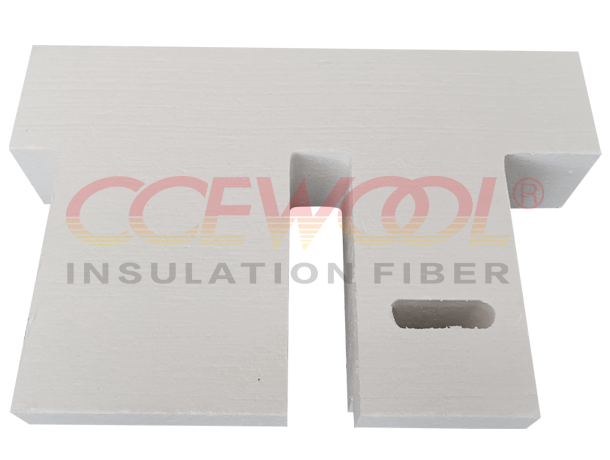

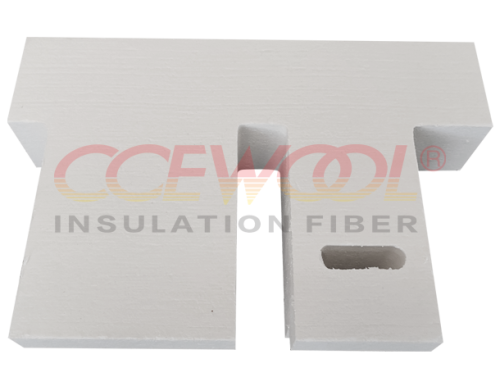

With its unique forming process and high-performance materials, CCEWOOL® HTIW Shapes offer an efficient thermal management solution for the photovoltaic industry.

Get a QuoteHighly efficient energy-saving solutions

Solar Panel Production: HTIW Shapes are used in solar panel production to provide insulation during high-temperature processes like cell sintering and lamination, ensuring optimal performance and energy efficiency.

Solar Cell Furnaces: These shapes provide thermal protection for furnaces used in the production of solar cells, improving energy efficiency and temperature stability.

PV Module Insulation: Used as insulating materials in the assembly of photovoltaic modules, helping maintain uniform temperature and enhance the durability of the final product.

Protection in High-Temperature Processing: HTIW Shapes protect components from high temperatures during the photovoltaic manufacturing process, improving both productivity and product quality.