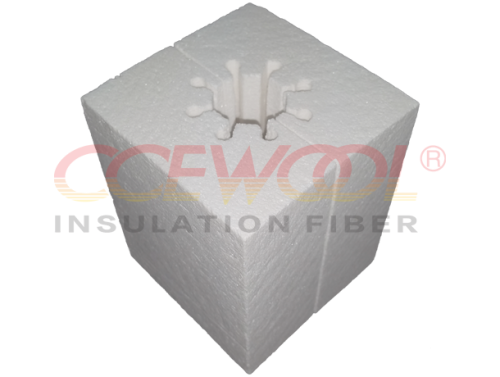

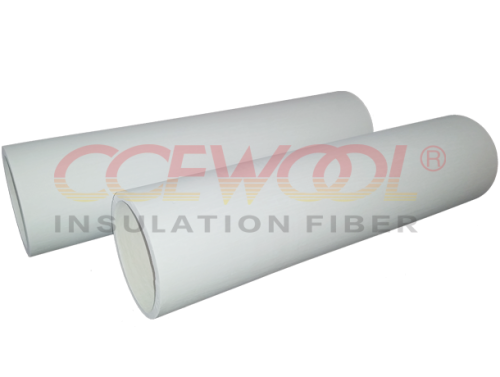

With its unique forming process and high-performance materials, CCEWOOL® HTIW Shapes offer an efficient thermal management solution for laboratory furnaces.

Get a QuoteHighly efficient energy-saving solutions

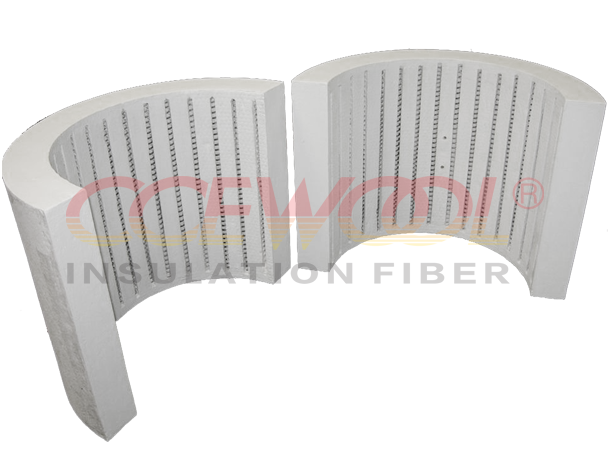

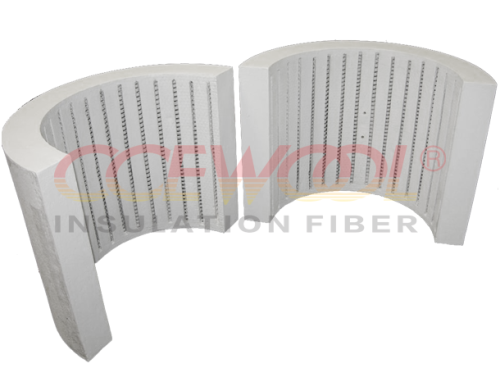

Furnace Linings: Provides high thermal insulation and protection for electric furnace interiors, ensuring stable operating temperatures.

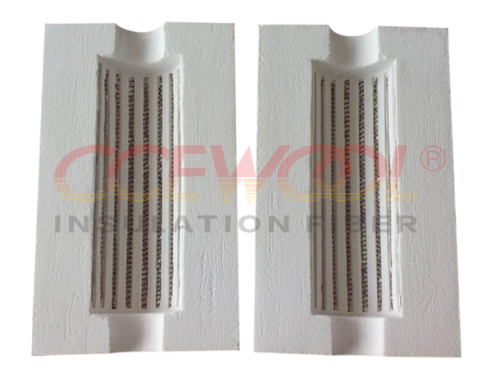

Heating Element Support: Custom shapes can support and insulate heating elements, improving efficiency and safety.

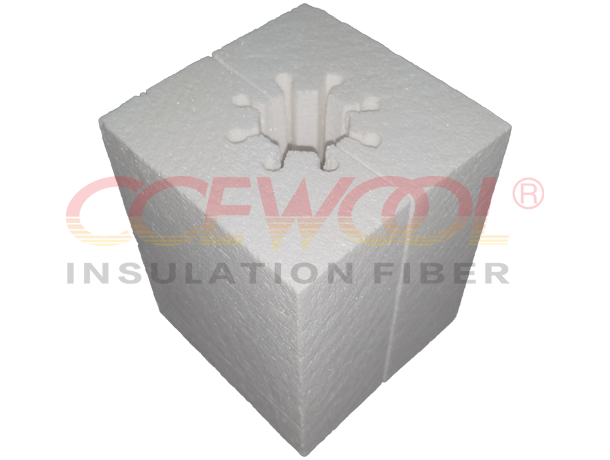

Thermal Shields: Acts as thermal barriers to protect sensitive components and maintain uniform heat distribution.

Test Chamber Insulation: Enhances thermal stability for precise experimental conditions.