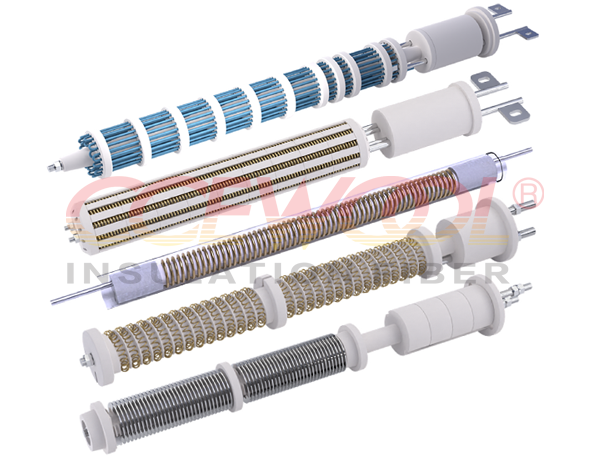

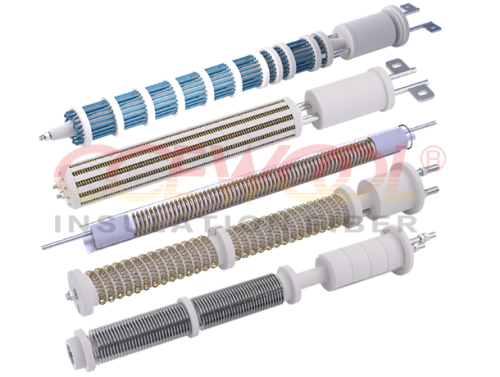

With its unique forming process and high-performance materials, CCEWOOL® HTIW Shapes offer an efficient thermal management solution for the electric radiant tubes.

Get a QuoteHighly efficient energy-saving solutions

Tube Linings & Insulation: Provides high-temperature insulation inside electric radiant tubes, reducing heat loss and enhancing efficiency.

Thermal Shields: Acts as a protective layer, reducing heat radiation and optimizing heat distribution.

Heating Element Supports: Supports heating elements, ensuring proper placement and long-lasting furnace operation.