With its unique forming process and high-performance materials, CCEWOOL® HTIW Shapes offer an efficient thermal management solution for the ceramic glass industry.

Get a QuoteHighly efficient energy-saving solutions

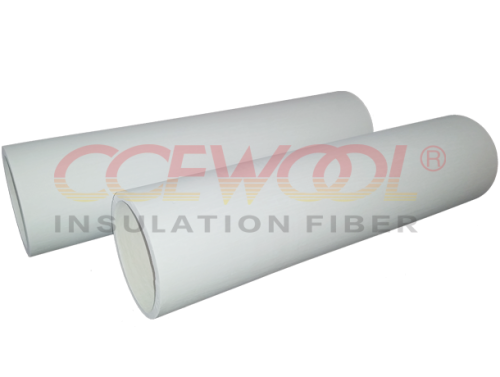

Glass Furnace Linings: HTIW Shapes provide high thermal protection for glass furnaces, helping to improve energy efficiency and stabilize furnace temperatures during production.

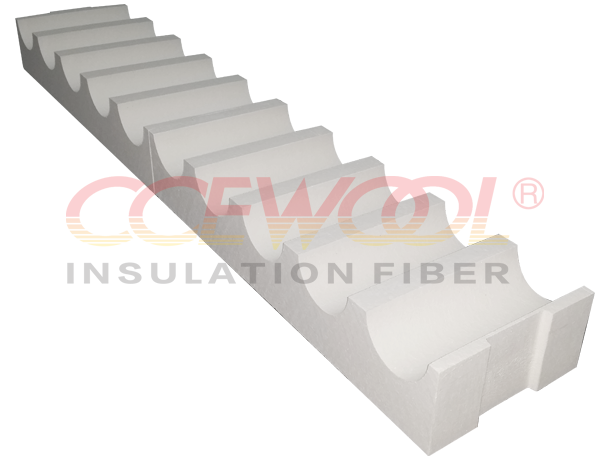

Glass Molds and Cores: Used to form molds and cores for glass casting, ensuring even heat distribution and minimizing energy consumption.

Kiln Insulation: These shapes are used in kilns for ceramics and glass, where their insulation properties help maintain the required temperatures and improve process efficiency.