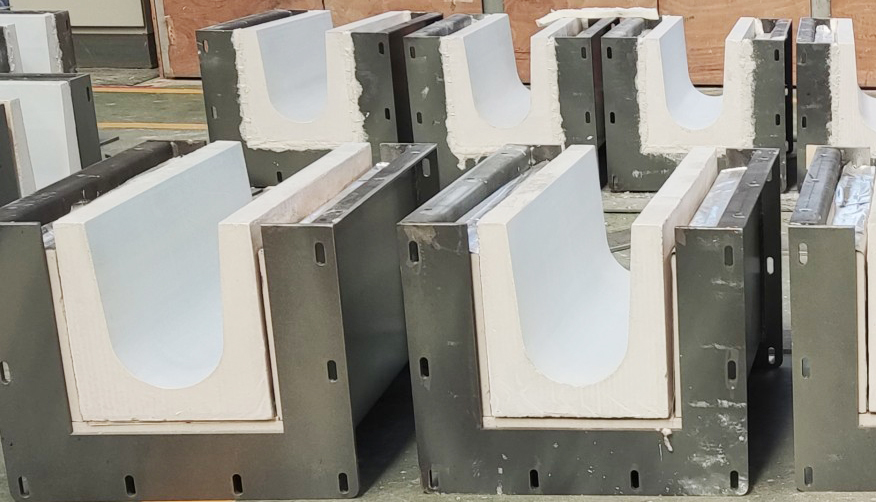

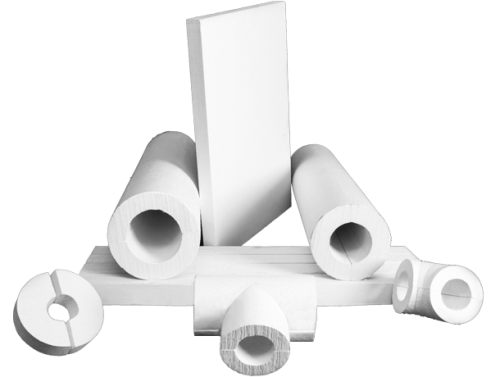

CCEWOOL® HD Calcium Silicate Board Custom Shapes use an asbestos-free formulation, making them environmentally friendly and safe. They are the ideal insulation material for transporting, transferring, and forming molten aluminum and other non-ferrous metals. In addition, the product performs exceptionally in mold manufacturing for the glass industry.

Get a Quote-

Customizable

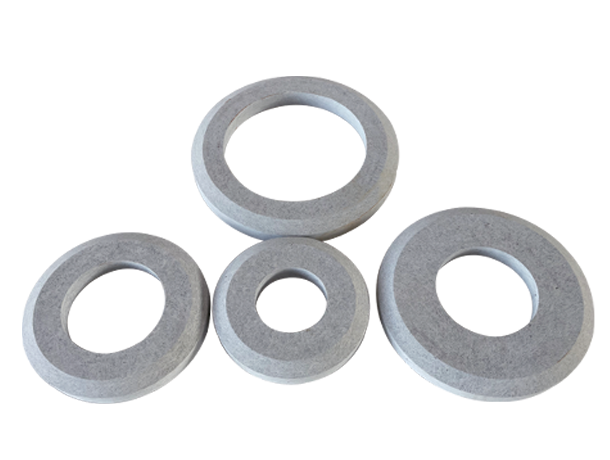

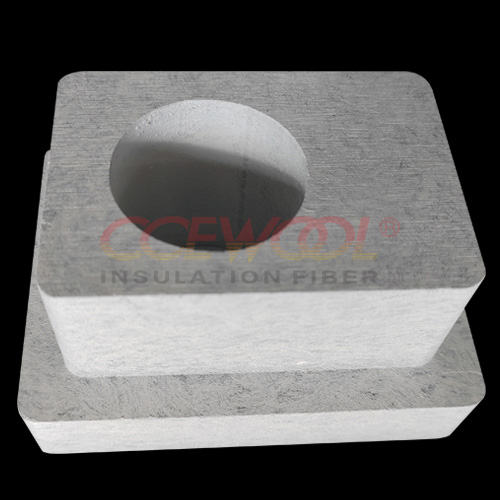

CCEWOOL® HD Calcium Silicate Board Custom Shapes can be customized to meet complex shape and size requirements for various applications.

-

Excellent Machinability

They are easy to process with high precision, making them ideal for fabricating complex parts.

-

Safe and Eco-Friendly

Free of asbestos and toxins, these products strictly comply with environmental standards.

-

Superior Anti-Aluminum Adhesion

Designed for environments in contact with molten aluminum and other non-ferrous metals, they maintain stable performance at high temperatures.