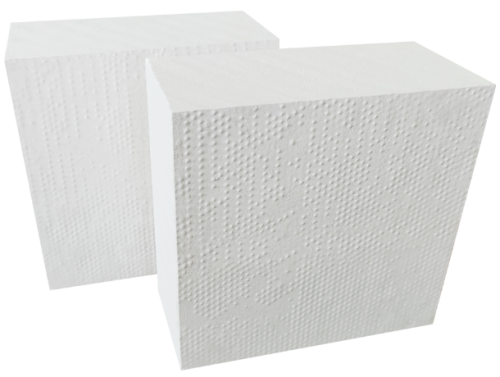

CCEWOOL® HD Calcium Silicate Board has a density of up to 1000 kg/m³ and a compressive strength of up to 20 MPa, making it ideal for high-temperature areas that need to withstand certain pressures. It also has an exceptionally long service life.

Get a Quote-

Precision Cutting for Easy Installation

Precisely sized, with polished surfaces and cut edges, ensuring safe and convenient installation.

-

Specialized High-Density Refractory Board

Designed for the non-ferrous metals industry, this board has a density of up to 1000kg/m³ and a compressive strength of up to 20MPa, making it suitable for high-temperature areas requiring pressure resistance.

-

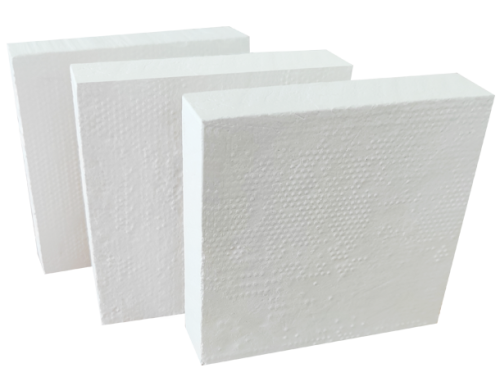

Durable and Long-Lasting

Calcium silicate boards can be reused for decades without compromising technical performance.

-

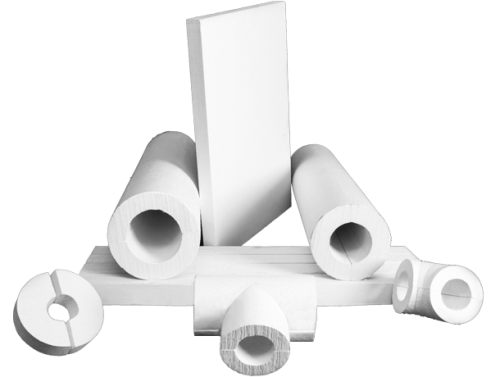

Premium Aluminum-Resistant Material

Capable of direct contact with molten aluminum without adhesion, its service life is five times longer than ordinary materials. It withstands temperatures up to 1000°C (1832°F).