Ceramic Thermal Blanket – CCEWOOL®

- 25 Aug, 2025

- Insight

In high-temperature industrial applications, insulation materials must not only provide excellent thermal performance but also remain stable during installation and long-term operation. The CCEWOOL® ceramic thermal blanket stands out for its flexibility and lightweight properties, allowing it to tightly conform to curved or irregular structures, minimizing gaps and enhancing overall insulation integrity. This makes it especially effective in furnace linings, pipe coverings, and complex thermal equipment.

Manufacturing Excellence: High-Purity Fiber + Double-Sided Needling

The superior performance of CCEWOOL® ceramic thermal blanket comes from advanced manufacturing techniques. Using in-house melted, high-purity spun ceramic fibers with long fiber length and low shot content, the blanket offers strong durability. Automated layering combined with double-sided needling ensures fibers are tightly interlocked, greatly improving tensile strength and structural stability. This process not only extends the product’s lifespan but also ensures resistance against fiber powdering or loosening in environments with strong hot gas flow.

Application Benefits: Durability Meets Efficiency

Thanks to its properties, the CCEWOOL® ceramic thermal blanket delivers long-term stable insulation performance, significantly reducing heat loss and lowering energy consumption. Its flexibility and strength also reduce maintenance needs, helping customers extend equipment life cycles while improving operational efficiency.

Brand Strength: Expertise and Reliability

With over 20 years of experience in high-temperature insulation manufacturing, CCEWOOL® is committed to full control over raw materials, process development, and strict quality inspection. Our products not only ensure consistent performance but also enjoy a strong reputation worldwide. Today, the ceramic thermal blanket is widely applied in metallurgy, petrochemicals, glass, ceramics, and other industries, driving energy-saving upgrades in high-temperature insulation systems.

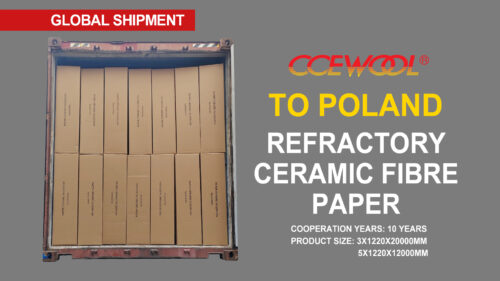

Spanish Customer

Cooperation Years: 7 years

Ordered Product: CCEWOOL® ceramic thermal blanket

Product Size: 25x940x7320mm / 25x280x7320mm

Since 2016, a long-term customer from Spain has been consistently purchasing CCEWOOL® products for seven consecutive years. Their latest order includes ceramic thermal blankets in sizes 25x940x7320mm and 25x280x7320mm. The customer highlighted the blankets’ excellent insulation performance, accurate sizing, and easy installation, noting their stability during long-term operation and the reduced frequency of maintenance. As a result, their annual order volume has continued to increase, strengthening the partnership year after year.

CCEWOOL® ceramic thermal blanket, with its outstanding flexibility, strength, and durability, provides customers with a long-lasting, energy-efficient solution for high-temperature insulation. With proven craftsmanship and reliable quality, CCEWOOL® will continue to deliver greater value to customers worldwide.