What is ceramic fiber gasket used for?

- 08 May, 2025

- Industry

In high-temperature industrial applications, the choice of sealing materials directly impacts equipment operational stability and energy efficiency. Traditional sealing materials often deteriorate or fail in high-temperature environments, leading to heat loss, equipment damage, and even potential safety hazards. As a sealing solution specifically designed for high-temperature conditions, ceramic fiber gasket stands out with its exceptional heat resistance and outstanding sealing performance, making it the preferred choice across numerous industries.

What is a Ceramic Fiber Gasket?

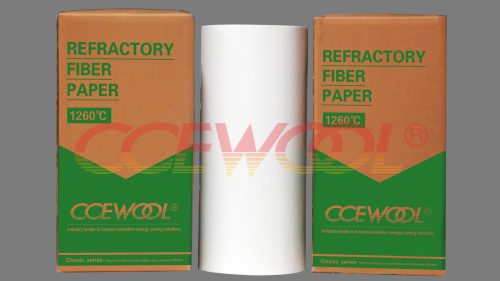

A ceramic fiber gasket is crafted from high-purity ceramic fiber paper through precision cutting processes. It can typically withstand temperatures up to 1260°C or even higher. It offers excellent flexibility, strength, and chemical stability, maintaining superior sealing performance even in high-temperature, corrosive, or high-pressure environments.

Why Choose CCEWOOL® Ceramic Fiber Gasket?

Exceptional Heat Resistance: Capable of continuous operation above 1000°C, maintaining sealing performance even under extreme conditions.

Superior Chemical Corrosion Resistance: Effectively resists the erosion of most acidic, alkaline gases, and corrosive media.

Excellent Flexibility and Easy Installation: Easily customized through precision cutting to fit complex sealing surfaces, providing outstanding adaptability.

Low Thermal Conductivity: Minimizes heat loss, improves energy efficiency, and supports energy conservation and emission reduction.

Environmentally Friendly and Non-Toxic: Made from high-purity materials without harmful components, compliant with international environmental standards.

In various harsh high-temperature environments, ceramic fiber gasket offers superior sealing, insulation, heat resistance, and corrosion resistance, becoming an indispensable material in modern industry. Choosing CCEWOOL® ceramic fiber gasket means choosing a safer, more efficient, and longer-lasting high-temperature sealing solution. Whether for new equipment installations or retrofitting existing systems, CCEWOOL® provides high-performance, customized sealing solutions tailored to your needs.